It is due at least once a year: the physical inventory process. Many people consider it a nuisance, yet it is absolutely necessary. First, it is required by law, and second, it is necessary to record the actual physical inventory. In order to take inventory with SAP with as little stress and time as possible, it is essential to have efficient mobile solutions for counting. As a result of digitalization, there is much new potential here in terms of the speed of inventory taking, which in turn leads to a reduction in costs.

Benefits of physical inventory process with SAP EWM and inventory types

Physical inventory refers to the regular physical stocktaking of all inventories at a specific point in time. The actual stock available and the accounted stock are compared in order to reveal possible differences. Despite the use of a warehouse management system such as SAP Extended Warehouse Management (EWM), such differences can arise when errors occur in the recording of receipts and issues. There are different inventory methods available for counting.

Perpetual inventory procedures

- Ad-hoc inventory (storage location and product-related)

This inventory method is manually controlled. The stock of a storage location or product is counted at an arbitrary point in time during the fiscal year.

- Low stock control / zero control (storage location related)

If the stock level falls below a defined threshold value after a removal from a storage location, inventory is triggered automatically. The person responsible for commissioning can register the stock without much effort, as only a small quantity or no quantity should still be present in the storage location.

- Storage inventory (storage location related)

Similar to the low stock control, the putaway inventory is also carried out during ongoing operations. The inventory takes place when the first stock is stored in a storage location in the fiscal year.

- cycle counting

With the cycle counting inventory method, products are inventoried at regular intervals within a fiscal year. The time intervals depend on the individual product.

- inventory sampling

Sample-based inventory can only be implemented in SAP EWM by connection to external software. This is not provided for in the standard.

Closing date inventory / annual inventory

Stocks are counted on a fixed date in the fiscal year. This method is used when permanent methods are not practical due to storage or organizational reasons, or when storage locations were not counted during the fiscal year because, for example, no stock removal took place.

Inventory process

The inventory process can be generally divided into three different phases:

- inventory preparation

During inventory preparation, the inventory documents with the stocks to be counted are created and activated, the products are blocked for postings, and the inventory documents are printed and distributed, if necessary.

- inventory count

During inventory counting, the stocks in the storage are counted and the counting result is transferred to the printed inventory document or, if a mobile solution is used, directly to the system.

- Evaluation and derecognition of the differences

The results of the counting are manually transferred to the system once they have been registered on the printout. If deviations occur, recounts can be initiated or the inventory difference can be taken off the books.

Process of inventory counting the SAP EWM standard

SAP Extended Warehouse Management offers a range of solutions for inventory counting. Depending on technical requirements, solutions are provided that support a paper-based or online inventory management processes.

The SAP GUI transaction and the Fiori application represent the paper-based process. The inventory document is created, released and printed on paper using the applications. The printed count list is distributed to the employees who register on it the counts that they take. Next, the counts must be transferred from the paper to the system. The advantage of this process is that no technical requirements (hardware, software, WLAN, etc.) must be met. However, recording the count on paper first and then transferring it to the system takes twice as much time. Furthermore, there is also the risk of errors occurring during the transfer.

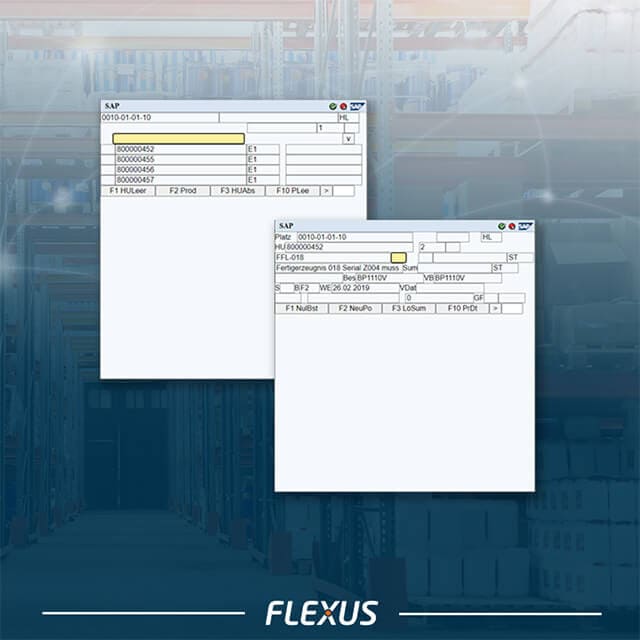

With the mobile RFUI solution in SAP, counting can be done directly online. A printout of the inventory document for counting is not required in this case because the corresponding data appears on the display of the PDA device. The counting results are entered on the mobile device and transferred directly to the system. The mobile SAP RFUI solution only supports the outdated ITS technology. The SAP applications are difficult to use and look confusing for many users. However, an intuitive user interface is imperative for applications that are only used once a year (in the case of periodic inventory).

Add-ons of Flexus AG

Flexus AG offers a mobile inventory solution based on SAP Fiori as an extension to the standard in SAP EWM. This inventory solution can be used to enter and save countings directly in the system. All functionalities of the SAP standard are fully integrated. The inventory solution by Flexus AG is enhanced by other useful additional functionalities such documentation for countings.

The well-organized and intuitive user interface assists employees in counting. This significantly speeds up work and reduces wrong inputs.

With a guided process for completion, countings can be signed and confirmed by the person who has done the counting directly at the scanner using Sign-On-Glass. A count list will be created as a PDF file and stored and archived in the SAP system. This means that neither the count nor the archiving requires a paper printout.

The inventory app by Flexus AG can be used device-independently. The modern Fiori interface will adjust to the different device types. For different hardware, individually optimized control concepts are supported. For example, a scan-based process can be run on PDAs while a touch-based process can be run on tablets. It is therefore possible, with a sample-based inventory in particular, to use all devices available in the company in order to complete the SAP EWM physical inventory management process as quickly as possible.

Advantages of the physical inventory management process with SAP EWM

With the mobile solution by Flexus AG, businesses can make the inventory process more efficient and secure. Countings can be done faster due to the simplified and optimized display. With the modern and well-organized user interface, the number of wrong inputs can be reduced. Digital archiving of the counting enables printouts to be avoided and counting results to be archived and traced for years without effort.

Last but not least, the system is complemented by an intelligent, task-dependent battery management system. In times of low workload, the vehicles are sent off to be recharged so that they can resume work on the transport tasks fully charged once the workload increases again.

Sources

Author – Roland Fakesch

SAP WM and EWM consultant

Working at Flexus, he provides consulting services for customers in the scope of mobile solutions under SAP WM and SAP EWM. Within this context, he implements projects and advises customers in individual process optimization.