The trend towards Automated Guided Vehicles (AGV) systems in intralogistics is steadily growing. This comes as no surprise given that AGV systems can help to cut costs and increase delivery dependability and reliability. Meanwhile, the objective should always be to integrate AGV systems seamlessly into the existing IT and logistics landscape. If it involves an SAP EWM system for Warehouse Management, it makes sense to have AGVs handle some of the warehouse tasks generated in EWM. This requires a communication interface between EWM and the control system, also called guidance system, of the AGV system manufacturer or the vehicles in order to distribute the warehouse tasks to the vehicles and to report back the confirmation to EWM.

Perfect integration of AGV logistics in SAP EWM with the AGV Guidance System by Flexus

This is where the Flexus Transport Guidance System (FlexGuide), including the AGV Guidance System, steps in. It is directly integrated into SAP and it creates transport tasks automatically according to the required warehouse tasks. Additionally, one or more AGV system manufacturers can be connected to the SAP system via the TGS API or VDA 5050 interface.

In AGV logistics, the distribution of transport tasks to the connected vehicles follows a flexible optimization logic. For example, the system will try to prevent or minimize empty runs by selecting the closest vehicle for a transport task. At the same time, waiting times should not be exceeded and due dates not be violated. These and other criteria are evaluated and factored in at runtime by the algorithms. As a result, an ideal distribution of transport tasks across the available automated guided vehicles (AGV) systems can be achieved at any time.

Hybrid control of a wide variety vehicle types and manufacturers in SAP EWM

A centralized control of vehicles with the TGS creates the capability to also control several AGV logistic system manufacturers simultaneously. With the standardized interface, these are easily integratable, and the central distribution by the TGS will always identify the best vehicle for a transport task, no matter the manufacturer.

Complex AGV logistics, which are mapped in SAP EWM via layout- or process-oriented Warehouse Management can be realized with multi-level transport tasks. This means that each subset of a warehouse task becomes a separate transport task. Depending on the plant topology, it is therefore possible to create transfers between automated and manned vehicles – fully controlled by the same system.

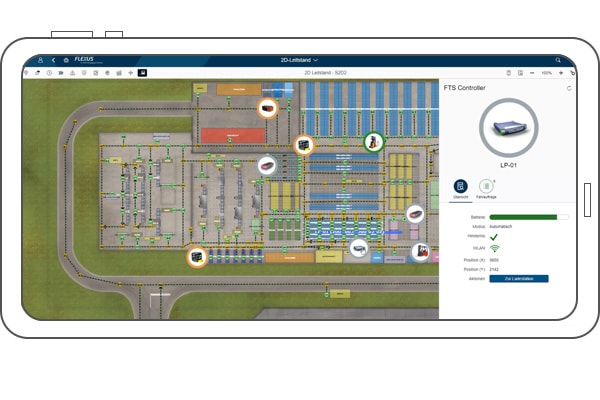

Traffic and battery management with the AGV Guidance System for SAP EWM

Apart from pure optimization and distribution of transport tasks, the TGS also handles the higher-level traffic control at critical spots. At intersections which are approached by two Automated Guided Vehicles (AGVs) at the same time, one vehicle is given the right of way and the other receives a command to wait until the intersection has been cleared again. If paths to be traveled are so narrow that two vehicles are unable to go past each other, these paths will be reserved for one vehicle exclusively to prevent the occurrence of deadlocks.

Last but not least in AGV logistics, the system is complemented by an intelligent, task-dependent battery management. In times of low workload, the Automated Guided Vehicles (AGVs) are sent off to be recharged so that they can resume work on the transport tasks fully charged once the workload increases again.

Seamless real-time integration between AGV systems and SAP EWM

At the end of the process, the automated guided vehicles (AGVs) confirm the successful transport back to the transport guidance system via the same interface. The system will check whether the corresponding transport order was created based on an EWM warehouse task and, if so, will automatically confirm it in the background. This makes the TGS a key link for the seamless real-time integration between SAP EWM and AGV system manufacturers.

Author – Christian Zerbes

Head of Transport Systems

In the course of his work at Flexus, he successfully implements projects in the field of Transport Systems. The projects range from the implementation of a simple forklift call system to the fully dynamic control of a wide variety of resources such as tugger trains, forklifts or automated guided vehicles.