Loading of the goods with SAP

In industry, one of the last intralogistics steps in the shipping process is usually the loading of the goods onto the forwarder’s truck. This process step is not yet digitally mapped in many companies today. However, digitalisation at this point can lead to great advantages in terms of process and legal security.

Process safety

To make the handling of trucks at the loading gates effective, the goods to be shipped are usually picked, packed and labelled before the truck arrives. The large load carriers are made available in the shipping zone. After the arrival of the truck, the goods are loaded from the shipping zone onto the truck with forklifts. Depending on the construction of the loading gates, the trucks are loaded from the side or via the rear ramp. This poses challenges in terms of process reliability. It is important to ensure that the correct goods are loaded onto the correct truck and that no large load carriers are forgotten. If the truck is used to deliver to several different destinations, the sequence of route planning must also be considered to ensure effective unloading of the goods at the destinations. For example, it can make sense to load goods that have to be unloaded first last, so that they are easily accessible.

Legal certainty

Another important issue when loading trucks is the correct securing of the goods. The load carriers must be secured in such a way that they are stowed safely. This means that the goods must not slip, tip over or fall down even during emergency braking and abrupt evasive manoeuvres. Section 22 of the Road Traffic Act states that the loader is responsible for the correct securing of the load. This duty cannot be transferred to the driver. For companies, this creates the risk of being liable in the event of traffic controls or even accidents involving the forwarder. One solution to this problem can be to document the proper securing of the load.

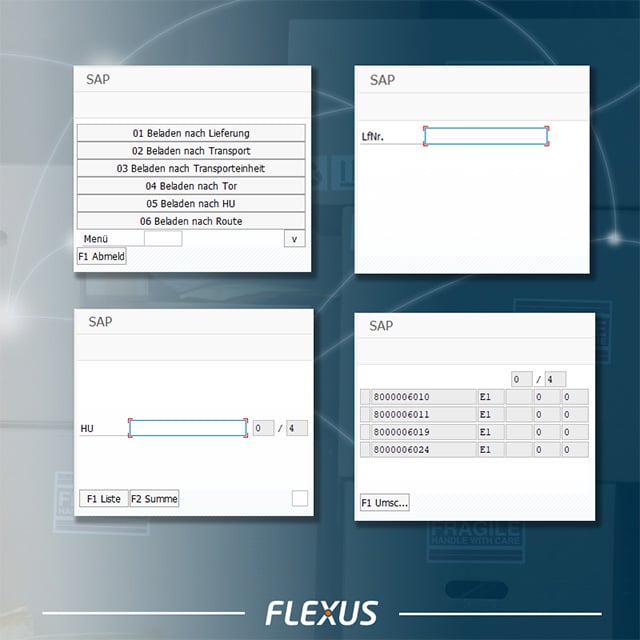

Solutions in SAP EWM standard

SAP Extended Warehouse Management offers an integrated mobile solution for SAP loading control within the RF framework. This solution supports the loading of handling units (= packages) onto the transport units by scanning barcodes. The sequence of loading can be specified from the route determination of the SAP TRM or SAP LE-TRA modules or left to the shipper’s discretion.

The application ensures that no handling units are forgotten or loaded onto the wrong transport unit. However, documentation of load securing is not supported by the standard solution.

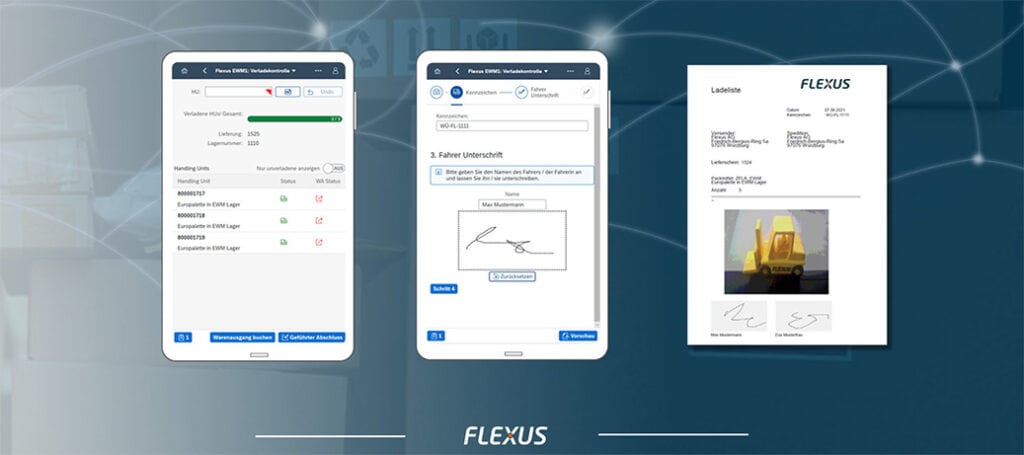

Add-ons of the Flexus AG

Flexus AG offers mobile solutions for SAP loading control in EWM based on SAP Fiori as an extension to the standard. The functions of the SAP standard are fully integrated in it and are supplemented by practice-oriented extensions. The user loads the handling units onto the truck by scanning the barcode and has all the required information, such as the progress, available at a glance. After successfully loading the handling units and securing the load, the user can complete the process. It is now possible to document the load securing by taking photos and confirming them with digital signatures of the loader and the driver. This information is used to generate a PDF document that contains the loading list, photos and signatures and is automatically stored in the SAP system at the correct document. Thus, it can be proven at any time that the load securing has been carried out properly. The Flexus AG solution is device-independent, i.e. it can be used on handhelds, forklift terminals, smartphones and tablets. The use of back-of-hand scanners is also supported so that employees can work hands-free.

Summary

By digitalising the loading process with SAP, companies can optimise their processes in several ways. SAP EWM offers the perfect platform for this. For simple SAP loading processes via handhelds, SAP already offers ready-made mobile solutions as standard. For improved usability, documentation of load securing and device-independent use, ready-made add-ons from Flexus AG can be implemented, which are continuously being innovatively developed.

Author – Patrick Bierbaums

Head of Mobile Solutions

As part of his work at Flexus, he successfully implements projects in the field of mobile solutions. Projects range from the simple implementation of individual apps to complete mobile coverage from incoming goods to outgoing goods. Projects in the field of maintenance are also implemented in the Mobile Solutions area.