Central logistics control through the transport guidance system

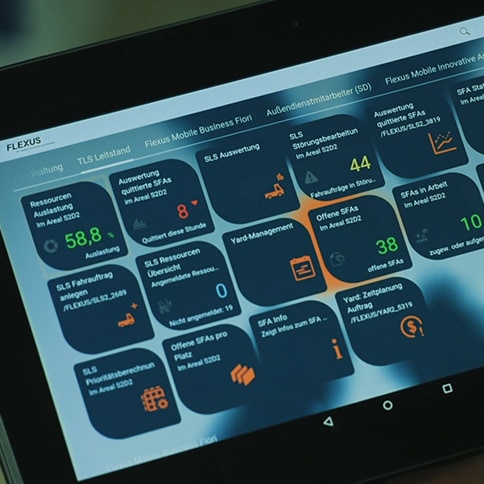

Intralogistics platform – Integrated and central control of the operational SAP logistics processes for SAP ERP and SAP S/4HANA.

“The savings potential and results of the FlexGuide transport and forklift control system from Flexus AG convinced us from day one. “

Armin Barth

Head of Logistics Bus Western Europe

EvoBus GmbH

Location Neu-Ulm

As part of the Daimler Buses division, EvoBus is not only Europe’s largest, but also one of the world’s largest leading bus manufacturer and produces touring, intercity and city buses at the Neu-Ulm site.

In order to ensure production supply, those responsible decided to use a networked and central SAP logistics system for material flow control.

Challenges in transport processing

The timed and untimed journeys are also controlled manually. A high level of empty runs, a disproportionate one the result was a fleet of vehicles and long response times. One problem with the use of tugger trains was that orders that were ready to be picked up along the way were not known beforehand. So no suitable followers or resources could be planned. In some cases, the individual tugger trains were overloaded or underloaded. With these major challenges, those responsible were looking for a partner to implement these requirements. They quickly became aware of the Würzburg SAP partner Flexus AG. With the FlexGuide transport/forklift guidance system for SAP, this offers a solution that fully covers a large part of the requirements as standard.

The FlexGuide allows various materials from the small parts warehouse to be bundled into one transport order. through the Real-time data transmission can be traced at any time exactly where the material is in the process. At the same time, the automated and utilization-oriented control of the transport volume ensures efficiency in logistics.

The system enables not only the simple and transparent control of the forklift fleet – it takes into account all existing resources that are necessary for the material flow in the company.

The functions include the optimization of forklifts, tugger trains, employees with mobile devices and internal truck traffic.

The FlexGuide represents a holistic approach for cross-departmental control and route optimization of the material flow. The implementation is designed for SAP ERP and SAP S/4HANA.

Efficient control of the means of transport

When supplying materials to the internal logistics areas, the various means of transport (forklifts, tugger trains, …) are efficiently controlled via the real-time client and the mobile terminals. This ensures transparency even in the confusing high-bay warehouse.

Demand-oriented planning of picking orders

Within the picking areas, there is a sequenced and needs-oriented employee deployment plan.

The visualization of the picking orders enables transparent order processing. Real-time data transmission enables paperless picking throughout. By connecting future-oriented technologies, the ergonomics of the employees are improved and sources of error are reduced at the same time. The dynamic control via the FlexGuide in operational logistics leads to flexible and efficient processes.

Efficient and optimized control of the tugger trains

With the FlexGuide, the tugger trains are also direct

controlled via SAP and supplied with driving orders. The

Tugger train control is based on route maintenance and tours and is an extension of the FlexGuide transport/forklift guidance system for SAP®.

A route describes a fixed sequence of source and destination locations that can be approached by a tugger train.

The automatic optimization and synchronization of all routes in real time ensures that production is supplied.

Even short-term changes are incorporated into the overall process by automatic recalculation.

The scheduled orders are visualized in a clear cockpit and can be edited in terms of sequence and assignment. For the tugger train driver, the current route including the route is displayed on a hall plan directly on the forklift terminal.

Optimized transfer of driving orders to the various means of transport

The driving orders are created automatically or manually via the Flexus worker dialog. This will guarantees the production supply and disposal of materials, empties and other relevant trips. The driving orders are optimized in a central order pool and on the various resources (stackers, tugger trains, picking trolleys, driverless transport systems).

Real-time key figure determination and active area control

The transmission of current key figures and faults reported by the system ensure transparency at all times and help problems quickly and easily

to be solved sustainably.

Processing, summarizing and providing real-time information in 2D and 3D increases traceability from goods receipt to assembly.

In conclusion

The use of the FlexGuide transport/forklift guidance system optimizes the entire internal material flow of EvoBus GmbH. Cost savings were made possible by lower personnel requirements, more efficient resource allocation and a resulting reduction in the fleet of vehicles. In addition, the automated control processes increase stability, quality and flexibility. The FlexGuide is used as the central picking and routing system at the Neu-Ulm site, and the roll-out to other Group plants is already being planned.

EvoBus GmbH is the largest European subsidiary of Daimler AG. With the Mercedes-Benz, Setra, OMNIplus and BusStore brands, EvoBus is a leading full-line provider.

As part of the Daimler Buses division, EvoBus is not only Europe’s largest, but also one of the world’s leading ones

bus manufacturer.