Efficient material flow control and inventory tracking in SAP EWM with Fexus Transport Guidance System

SAP can look back on a long history of goods movement and inventory management. From the simple Warehouse Management in MM to the first true Inventory Management in WM all the way to the latest product SAP EWM, which continues the consistent development and lifts Inventory Management into the new world of S/4HANA. EWM (Extended Warehouse Management) gains traction not only because of the announcement by SAP that it will no longer provide WM with new functions and that support will be discontinued. It is also the extended range of functionality that convinces many customers to migrate their existing warehouse from WM to EWM or to implement new projects directly for SAP EWM.

Potential of SAP EWM in the field of materials flow control

Complex processes such as goods receipt, storage, production supply or goods issue can be mapped in the standard system and can be adjusted with great flexibility as a result of the high degree of Customizing. For the first time, true multi-stage goods movements can be mapped via the layout- and process-oriented storage control. Compared to WM, search strategies, handling unit management and organizational structures have been improved.

Shortcomings of SAP EWM

Yet, there are some areas where SAP EWM falls short. Despite the existence of resource management or queue management, the distribution of warehouse tasks to individual resources – meaning all types of vehicles such as forklifts, electric lift trucks or tugger trains – can be controlled with greater efficiency. The minimization of empty runs by assigning a warehouse task to its closest resource is almost non-existent.

Boosting efficiency, in particular, with implied cost reductions is becoming increasingly important in the age of digitalization that we today live in. Likewise, the end user gets a more comprehensive application in terms of functionality with the RFUI framework but the solution leaves something to be desired in terms of usability and design. Although this is exactly what SAP has openly committed to with the introduction of Fiori and UI5, SAP has yet prove this due to the lacking EWM Fiori standard apps.

Optimization of the existing SAP EWM systems with the Flexus Transport Guidance System

Flexus addresses precisely this niche with the Transport Guidance System (FlexGuide). The goal is to handle the entire movement of goods in a factory as efficiently and therefore with as few resources as possible. The system accomplishes this by placing a strong focus on the minimization of empty runs – both in terms of quantity and quality. The system core, which takes into account not only empty runs but also waiting times, due dates, manual priorities and other factors, manages the central transport task pool and always makes the right decisions due to optimization algorithms.

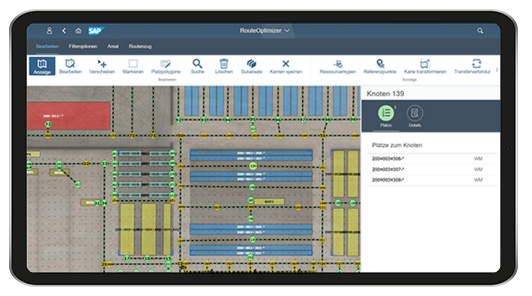

An advanced warehouse topology, which requires not only storage bins but also an accurate specification of the location as well as a path network, is necessary for the decision making process. The FlexGuide -TGS RouteOptimizer solves this task in a visual manner by drawing storage bins as nodes on a 2D map. These nodes are then linked with paths, so-called edges, which can only be used by certain resource types.

The result is a network of paths that allows the system to determine the distance between any two points while respecting intersections, turns and one-way streets. And this, in turn, forms the foundation for the calculation of empty runs during the determination of the best resource for a transport task.

Use of multi-stage transport task with resource type changes

Implicit resource type changes, in other words multi-stage transport tasks, are a result of this path network. As an example, the paths in the aisles of a high-rack warehouse are only permitted for narrow-aisle forklifts, while only front forklifts are allowed to move on the path outside. The system recognizes that a storage operation from goods receipt to the high-rack warehouse cannot be carried out with one transport task and splits it at the outer location in front of the correct high-rack row. This multi-stage capability is also not limited to a single split but can generate any number of transport tasks, if required. The implicit multi-stage capability based on the path network can additionally be complemented by explicit Customizing, the so-called “logistic routes”.

This function strongly resembles the layout-oriented storage control from EWM. Through Customizing tables, it can be set there that warehouse tasks are split up at defined buffer locations based on the selected conditions (e.g. source/destination storage type, movement type, etc.). The FlexGuide can replace this rather tedious and quickly confusing Customizing with the intuitive visual maintenance in the RouteOptimizer, without losing any flexibility through the addition of logistic routes. This is not an either-or decision. The TGS is also capable of mapping the layout-oriented storage control, and therefore the split of storage tasks with transport orders, in exactly the same way as it is set up in EWM. It can even extend it, if necessary.

Warehouse tasks as transport tasks in SAP EWM

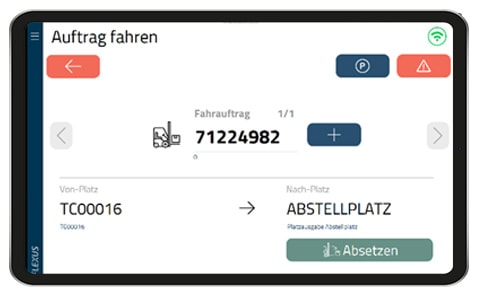

Speaking of transport orders: these constitute the central element of FlexGuide and represent a goods movement between a source location (position from) and a destination location (position to). The transport tasks are either created automatically by postings in the SAP system or manually by end users. With EWM integration, warehouse tasks are automatically converted into transport tasks. The BAdi implementation for the creation of an EWM warehouse task is therefore extended by a standard module of Flexus, which transfers all essential information such as source and destination location, product number, quantity, weight or HU type into the transport task. The transport task ends up in the transport task pool and will then be efficiently distributed to resources by the system core by use of the optimization algorithms. The great advantage of this central transport task pool is that transport tasks from other sources can also be stored there centrally. These may be other SAP modules such as WM, PP, IM or PM or manually created transport tasks without SAP reference. Movements for waste, chips, scrap or empties are often not mapped in EWM and have to be moved system externally. The more of these movements end up in the FlexGuide transport task pool, the higher the potential to minimize empty runs by intelligently combining interleaving tasks.

Fronted design for the best user experience

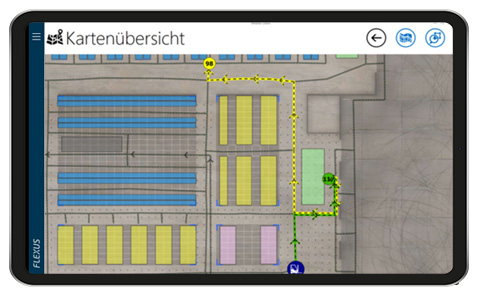

The comprehensive approach does not end here, however, but includes the end user – in other words, the driver. The driver is provided with a user interface that is as easy to use as possible and offers a high level of visual design. For this purpose, Flexus provides software clients and interfaces for the most common end devices and operating systems, including SAP Fiori. That includes vehicle terminals and tablets with Windows 10, as well as smartphones and tablets with Android or iOS. On these end devices, the driver is guided from task to task in a dialog-based approach, with context-sensitive display meaning that only the information needed to fulfill the current task is shown. The driver can choose to open a 2D overview that displays his/her current known position, the source and destination location of the current transport task, and the shortest route to get there. This is a valuable support especially for new employees or newly created warehouses. If a user confirms his/her assigned transport task, which is based on an EWM warehouse task, this is also confirmed in real time in the background.

Summary

The FlexGuide provides a useful extension to the SAP EWM system and intentionally sets itself apart from it. Customer projects that have already been implemented and are running an existing EWM system can be extended. In contrast, in a migration project to EWM, the TGS is directly included in the concept phase and then seamlessly blends into existing processes.

Similar to the SAP history towards SAP EWM that achieved several milestones, FlexGuide has also evolved with many additional add-ons and innovative technologies. For example, a dynamic tugger train control can be integrated, which extends the system to include GLT or KLT (large load carrier/small load carrier) tugger trains. Automated Guided Vehicles (AGVs) from various manufacturers can be connected using a standardized interface. In many areas, the first artificial intelligences are already available that can make better decisions based on historical data. The use of these innovative technologies will make sure that the FlexGuide will stay up-to-date with the latest trends in technology and offer a tangible added value for customers.

Expert network EWMinds

Together with our partners Priotic GmbH, IT-Forum and OPAL Associates Holding AG, we offer in the expert network EWMinds the complete handling of logistics processes with SAP EWM. As a Business Suite provider, we consult our customers holistically during the migration or new implementation of SAP EWM with own SAP add-ons, tools and hardware.

Author – Christian Zerbes

Head of Transport Systems

In the course of his work at Flexus, he successfully implements projects in the field of Transport Systems. The projects range from the implementation of a simple forklift call system to the fully dynamic control of a wide variety of resources such as tugger trains, forklifts or automatic guided vehicles.