REAL-TIME LOCALIZATION OF GOODS AND FORKLIFT VEHICLES WITH SAP

In combination with the FlexGuide transport/forklift control system for SAP ® , vehicle/forklift tracking offers a comprehensive control instrument for all internal transports.

The material movements carried out are transmitted to the SAP system in real time.

This ensures scan-free storage processes and additional functions, such as B. allows the collision warning.

FUNCTIONALITY AND AREAS OF APPLICATION

Vehicle/forklift tracking is recommended if:

- Your warehouse is characterized by high turnover dynamics

- You have to spend a lot of time looking for goods

- You want to significantly minimize the number of your incorrect deliveries

Through the combined use of location technologies with sensors (height and loading sensor), it is possible to validate the recording and parking of the driving orders without scanning in SAP ® . This significantly maximizes the efficiency of transport processing.

Route display

With the use of vehicle navigation within SAP intralogistics, the shortest route to the starting point is displayed to the driver on his terminal.

The load carrier to be picked up is marked in color and picking it up or putting it down is automatically registered via the vehicle location.

Warehouse and logistics managers benefit from enormous time savings, since the employees carry out the transport processing intuitively and without time-consuming scanning processes.

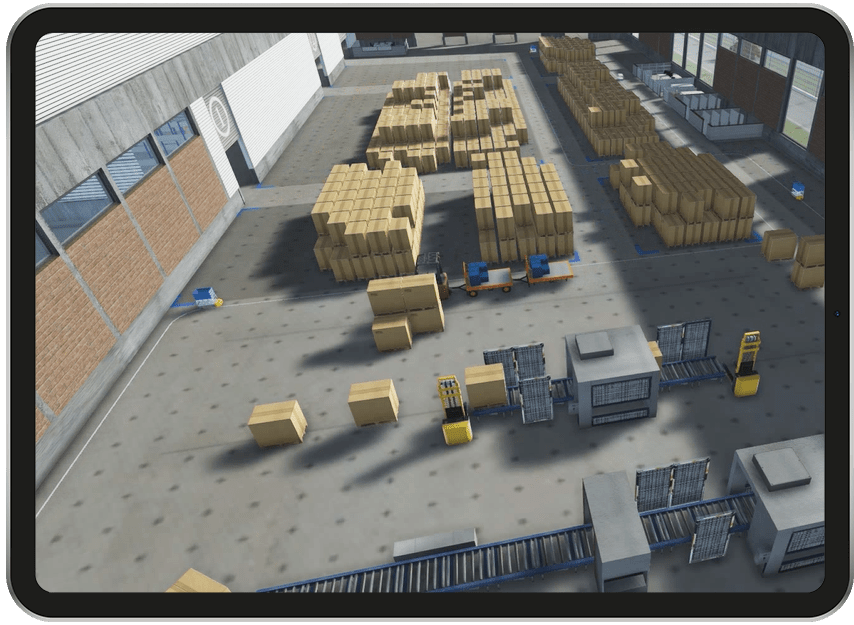

Innovative dashboards

Various SAP dashboards are available to the warehouse/logistics manager for evaluation and transport control.

These are displayed as a 2D/3D cockpit . This allows the current position and capacity utilization of the vehicles (forklifts, tugger trains, driverless transport vehicles) to be continuously tracked.

In this way, all intralogistics processes can be controlled proactively.

TECHNOLOGIES FOR VEHICLE / FORKLIFT LOCATION

There are various technologies for locating vehicles. Locating by laser, RFID tags or camera-based systems enables permanent vehicle tracking. This not only ensures process reliability , but also various driver assistance systems (e.g. for navigating the driver) can be used.When locating via ultra-wideband (UWB), the position of the vehicles is determined based on the transit time of a radio signal between one object and multiple anchors. The vehicle to be located is equipped with a small tag. This sends the position of the vehicle in real time to the corresponding anchor with an accuracy of 10 – 30 cm. Geofencing can be used to automatically trigger an action (e.g. acknowledgment of a driving order). In addition, extended security functions are enabled. For example, it appears a collision warning appears on the driver’s display when two vehicles approach, so that accidents are also reduced in confusing warehouse situations. In addition, the speed can also be regulated automatically via the FlexGuide transport/forklift control system in dangerous situations.

PRECISE FORKLIFT LOCATION VIA 2D LASER LOCALIZATION

Our FlexGuide transport/forklift control system can be sensibly supplemented by laser localization. Customers benefit from scan-free storage, retrieval and transfer processes. The laser does not orient the forklift to artificially generated reference points on your factory premises, but to its real and current environment. As a result, changes in its dynamic environment are immediately recognized and taken into account when navigating indoors and outdoors.

Benefits of vehicle/truck tracking with the FlexGuide

- Automatic goods and storage location identification with SAP ®

- Save time and increase efficiency through automated scanning processes and identification of objects

- Localization of your forklifts both inside and outside your company

- Intelligent localization and identification solution for SAP ®

- Detailed statistics on the utilization of your resources

The combined use with the FlexGuide transport/stacker control system offers a high degree of automation and optimization potential in the environment of the entire intralogistics.