For more than 25 years now, Flexus AG has been developing products for intralogistics, advising customers and partners on efficient processes and carrying out projects in all areas of the plant: from yard management to forklift and AGV control systems to maintenance and mobile apps for SAP. With our new focus on SAP EWM, a new chapter begins for Flexus AG, whereby this is a good time to look back and take a closer look at the developments in intralogistics over the past 25 years.

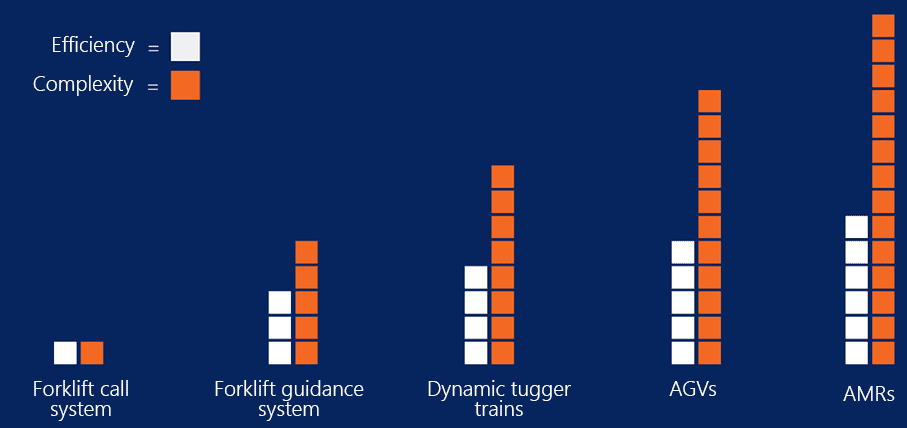

Since the foundation of the company, our goal has been to improve the processes of intralogistics, both through good advice, but also through suitable, self-developed products, so these products are a good benchmark to document the change in the industry. What becomes clear quite quickly and should also be known to all professionals in the industry: The efficiency of processes and systems has increased significantly, while their complexity has also increased.

In this article, we want to show how efficiency has increased in relation to complexity, what requirements and problems different solutions bring, and what will be the main challenge of the entire industry in the future.

1. Forklift call system

The simplest way to organize transports in a warehouse or plant is with a forklift call system. In this, an arbitrary number of forklifts drive “arbitrary” driving jobs in “arbitrary” order. Often these driving assignments can be found printed out on a bulletin board or in a box. The driver takes one or more orders and then drives them.

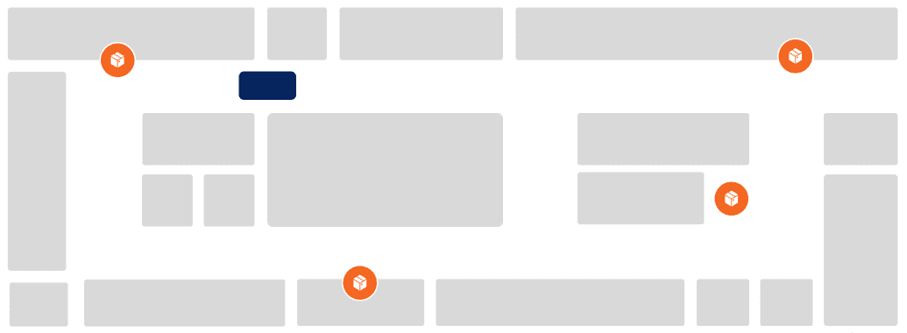

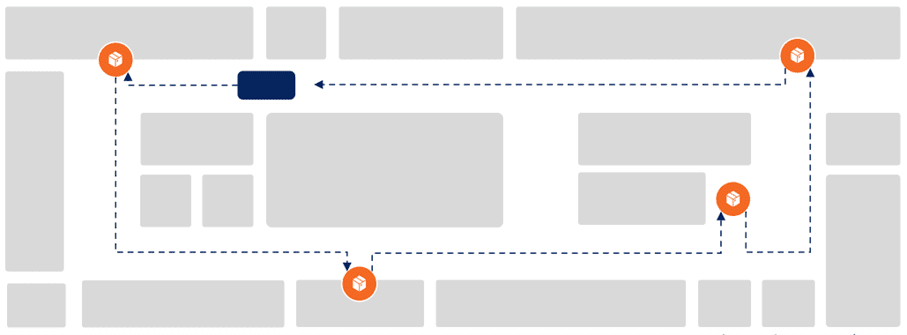

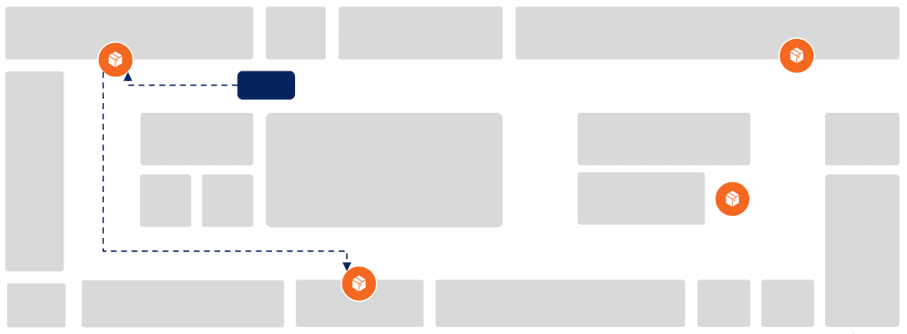

In the following graphic, a warehouse is shown in gray, the locations where transport orders must be picked up are shown in orange, and a resource, for example a forklift truck, is shown in blue:

With a forklift call system, there is no optimization of the sequence and allocation of the driving jobs. Path planning or digitized processing is also rarely available.

The advantage of this system: simple and without great complexities. However, efficiency is highly dependent on the knowledge of individual employees. Furthermore, there is little to no optimization and due to the lack of digitalization, there is no transparency and evaluation possibilities.

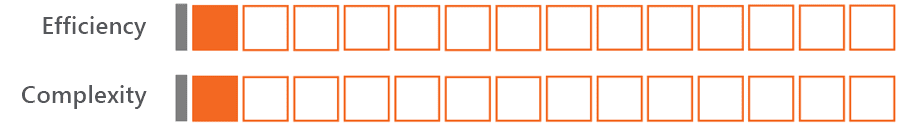

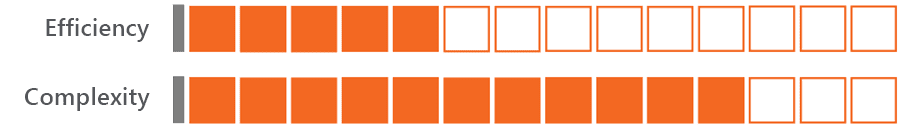

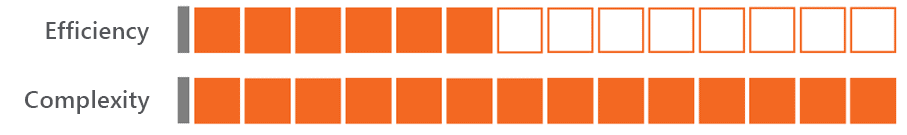

Greatly simplified, one can give the forklift call system one point for efficiency and one point for complexity:

Important:

The number of points awarded is subjective and are different in each work and process. The points given here refer to estimated average values of our projects. The two categories “efficiency” and “complexity” are also highly simplified. A closer look would have to consider 20 to 30 different categories.

In order to maintain clarity for this article, we define “efficiency” not only as the utilization of vehicles, but also their plannability, punctuality, error frequency and many other points. Under “complexity” we summarize the entire process and project complexity, so it includes not only logics and calculations, but also topics such as monitoring, error handling and exceptional situations.

2. Forklift guidance system

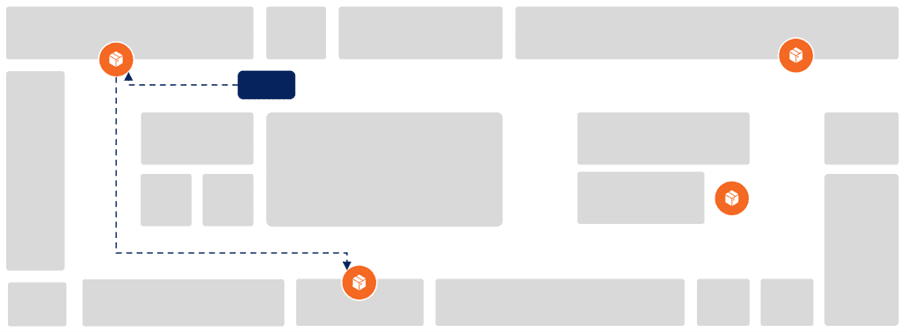

In a forklift guidance system, driving jobs are collected by a central system, evaluated according to various criteria, optimized and then assigned to selected resources or forklifts.

Thanks to central optimization, it is now possible to optimally plan routes, reduce empty runs and avoid delays. Furthermore, the digital mapping makes it possible to create evaluations afterwards in order to analyze when and where process steps were carried out inefficiently or where a particularly large number of errors occurred.

However, this digitization is already the first additional challenge and complexity: In order to be able to use a forklift control system, all driving orders must first be complete and digitally available. This can lead to previous processes having to be adapted, changed or, in some cases, even further IT systems having to be introduced.

In addition, other hardware comes into play alongside IT systems and changed processes. Terminals or tablets on the forklifts are necessary so that the drivers can see the driving orders. Scanners are often used for proper validation, and now they are added to the mix. Furthermore, complete WLAN coverage is necessary, which is not the case everywhere.

In summary, it can be said that a central forklift control system can significantly increase efficiency, but this is also associated with an increase in complexity. New IT systems, hardware and processes are all introduced at once and must work together perfectly.

3. (Dynamic) Tugger trains

Especially when many small containers have to be transported, tugger trains are often used. These transport not only one driving job like forklifts, but significantly more, sometimes over 100.

The classic route train has a fixed route, i.e. it travels a fixed sequence of stops in the warehouse and production. In addition, it often has fixed start times, for example, once on the hour. This can be solved much more efficiently by dynamic route trains: On the one hand, the route can be flexibly adapted to the transport orders to be transported so that it becomes shorter. On the other hand, the tour itself can be improved. The tugger train does not have to wait until the hour to start, but leaves when either a due date would be broken in production or it is fully loaded.

Dynamic route planning in particular makes it possible to use tugger trains much more efficiently. However, this assumes that tours and routes can be optimally planned in advance for the near future.

For this to be possible, for example, preceding processes in order picking must be precisely coordinated with route train planning. Only if the necessary and planned materials are ready, the tugger train can transport them. Production cycles must also be taken into account and integrated into the system.

Here, too, it can be summarized that modern systems, processes and algorithms make it possible to achieve significant increases in efficiency, but that complexity, especially due to interlinked processes, increases massively.

4. Track-based AGVs (Automated Guided Vehicles)

In recent years in particular, more and more AGVs are being used which, although they are track-bound, can carry out driving jobs completely autonomously. Lane-based driving means that standardized concepts, such as the AGV standard VDA 5050, can be used to manage traffic. A good example is Safelog, whose AGVs can be controlled 100% standardized via VDA 5050.

The basic principle of a guidance system for AGVs hardly differs from that of a guidance system for forklifts. However, there are additional requirements such as traffic management, battery management, or dead-lock resolution that human drivers can solve on their own.

In particular, dealing with errors and exceptional situations poses the greatest challenges to an AGV transport system. From dead-locks at intersections, obstructed pathways, dirty sensors to communication glitches, there is great potential for error.

However, AGVs behave predictably and do not rely on human labor or knowledge. Thus, efficiency in warehousing and production processes can often be increased by using them, if the additional complexities can be managed.

If the robots are equipped with additional sensors and software, some of them can also be decoupled from the lane-based driving mode and independently as well as autonomously find a way to the target location and drive there. In particular, MiR with its versatile top modules and Magazino with its completely new approach – the combination of route tug and AMR – perfectly combine autonomous driving with innovative transport concepts.

This autonomous driving mode enables the robots, for example, to independently avoid obstacles such as parked pallets or temporarily parked other vehicles in order to quickly reach their destination without waiting. Evasive maneuvers can also be performed partially independently to reduce exceptional situations in which humans must intervene.

However, this autonomous path planning must also be coordinated. Especially with fleets of vehicles from different manufacturers, this becomes much more complex and difficult when vehicles drive more “unpredictably” and take evasive action on their own or calculate new routes.

The most important challenge of intralogistics

From simple forklift call systems to fully autonomous tugger train AMRs, a lot has happened in the last 25 years. Both hardware and software for intralogistics solutions have evolved steadily, leading to ever greater efficiency gains.

At the same time, however, complexity has increased along with it, and not just linearly, but exponentially in some cases. In addition to the solutions presented, most plants and warehouses have mixed operations. This means that several of the solutions are used simultaneously. On the one hand, this enables the best transport methods to be used for individual processes; on the other hand, these different systems and processes must also be coordinated with each other.

Conclusion: Evaluation and conscious use of new technologies

The conclusion of this article is not that the newest and most efficient system should always be used everywhere. On the contrary, all these new technologies should be evaluated and used consciously with the knowledge that not only efficiency will increase, but also the complexity of systems and processes. In some situations, the added value from increased efficiency cannot be justified by the additional complexities.

At Flexus, we see our role as not only developing more efficient products or helping customers use more efficient hardware, but also managing complexity:

- It is just as important how exceptional situations and errors are handled as it is to increase the utilization of the individual vehicles.

- It is as important how comprehensible the algorithms and solutions are as how to reduce empty runs.

- It is as important to be able to easily analyze problems and other data sets as it is to minimize waiting times at intersections.

Efficiency comes automatically through new technologies and their possibilities. The main challenge will be how we deal with the complexities that come with it.

Author – Alexander Popp

SAP Consultant TLS

Within the scope of his work at Flexus, he is active in the development of new applications as well as in the consulting and implementation of projects. The focus is on the transport guidance system for AGVs and tugger trains. Across topics, he is responsible for the development of new FlexRules.

Author – Dominik Grasser

AI Developer

As part of his work at Flexus, he optimises the intralogistics of our customers with the appropriate optimisation algorithms. This is mainly applied in the optimisation of forklifts, tugger train logics and the efficient control of AGVs.