Definition: What is a goods receipt?

Goods receipt is a process in which a company receives and accepts delivered goods. The delivery is accepted, checked for correctness, completeness and quality and then recorded and stored.

This process marks the transition from suppliers to internal warehousing and is of great importance for the efficient management of your inventories. It is the counterpart to goods issue.

Goods receipt process

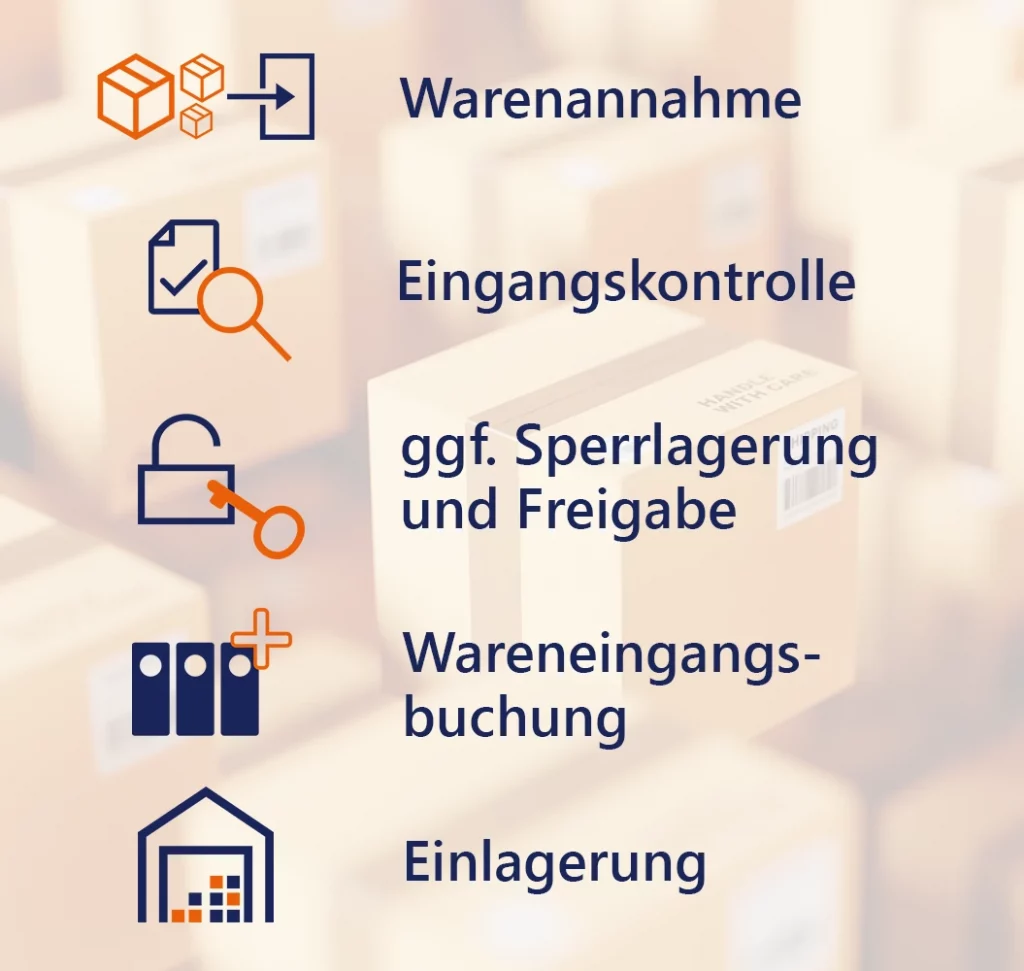

Goods receipt in logistics is divided into five main steps:

- Goods receipt: In the first step, you physically receive the delivered goods. Carry out a plausibility check using the delivery documents (“Are the goods for us?”). During a superficial visual inspection, recognize and document any damage or deviations. Confirm warning acceptance with a signature.

- Incoming inspection: This is followed by a detailed inspection of the completeness, correctness and quality of the goods. You should check the products for external damage, defects or deviations from specifications. If necessary, carry out random tests. It is important to provide complete documentation, stating the name of the inspector.

- Blocked storage and release if necessary: Some deliveries require additional checks, e.g. goods with a required customs release. In this case, the corresponding goods must be deposited separately for inspection. If the goods meet the requirements, they are released.

- Goods receipt posting: Information about the goods received, including item number, quantity and quality status, is entered into your warehouse management system. This ensures accurate updating of stock levels and enables goods to be tracked.

- Putaway: Finally, store the goods in the appropriate storage areas. You should take into account factors such as item type, size and storage space availability. This ensures efficient warehouse organization and use. The goods are now available for goods issue.

Interfaces to other processes

Goods receipt is usually the first process within warehouse management. It is therefore directly adjacent to the processes of the upstream area – the yard. To enable a seamless transition here, it is advantageous if the respective management systems communicate seamlessly with each other. FlexYard Management offers you optimum conditions here thanks to its complete integration in SAP. This allows you to record, manage and retrieve the movement of goods in the system across all processes and areas, from truck notification to unloading and storage.

How to optimize your incoming goods

We have a few tips for you on how you can make your incoming goods process more efficient:

- Prioritize the processing of goods based on urgency and order quantities.

- Ensure that your staff are trained in the incoming goods process to avoid errors and delays.

- Make a storable packaging agreement to avoid repackaging on receipt of goods.

- With suitable warehouse management software such as SAP EWM, you can efficiently record and manage incoming goods.

- Use barcodes and scanners to speed up the identification process for incoming goods.

- Carry out regular analyses and implement improvement measures for your processes.