Mobile Instandhaltung mit SAP und Flexus

Digitalisieren Sie Ihre Wartungs- und Reparaturprozesse mit FlexMaint, der mobilen Instandhaltungslösung der Flexus AG. Für weniger Stillstand, höhere Anlagenverfügbarkeit und maximale Effizienz.

Echtzeit-Integration in SAP

Papierlose Prozesse

Volle Transparenz

Schnelle Rollouts & einfache Bedienung

Flexmaint

Mobile Instandhaltung mit SAP – effizient, transparent und flexibel.

Mit den Flexus Add-Ons auf Basis von SAP Fiori digitalisieren Sie Ihre Wartungs- und Reparaturprozesse vollständig – für längere Anlagenlebensdauer, weniger Ausfälle und eine moderne, papierlose Instandhaltung.

Flexmaint

Unsere SAP PM-Berater bringen Sie auf den richtigen Weg!

Optimieren Sie Ihre mobile Instandhaltung. Wir unterstützen Sie gerne bei der Umsetzung Ihres PM Projektes!

Kundenmeinungen

Was unsere Kunden sagen

FlexMaint Vorteile

Verbinden Sie Planung, Ausführung und Rückmeldung in einer Lösung

Verarbeiten Sie Meldungen und Aufträge mobil

Ihre zuständigen Mitarbeiter haben jederzeit und direkt vor Ort Zugriff auf alle relevanten Daten, Dokumente und Funktionen, die für die Durchführung der Instandhaltungs- und Servicetätigkeiten von Relevanz sind.

Lösen Sie papier-basierte Prozesse ab

Durch das mobile Management der Instandhaltung entfallen papierbasierte Prozesse und die redundante Datenerfassung vollständig, da Ihre Mitarbeiter diese just in time direkt in SAP hinterlegen.

Laden Sie Bilder, Dokumente & Videos hoch

In der Auftragsanlage und der Rückmeldung können Sie Daten hinterlegen, die für das Erbringen der Tätigkeit nötig sind. Auch Dokumente & Fotos zur genaueren Dokumentation können Ihre Mitarbeiter so dem passenden Auftrag in SAP zuordnen.

Melden Sie Arbeitsschritte direkt am Einsatzort zurück

Die Rückmeldung per mobilem Endgerät ermöglicht Ihnen einen zeitoptimierten Prozessablauf. Informationen zur Arbeitszeit oder dem Materialverbrauch können Ihre Mitarbeiter noch vor Ort melden & dadurch sofort einen neuen Auftrag starten. Wählen Sie selbst, welche Bereiche von der Wareneingangslogistik, der Lagerverwaltung, der Produktion bis zum Versand abgedeckt werden sollen.

Ad-Hoc Wartung und geplante Wartung

Mit der Lösung können Sie sowohl geplante Wartungen auf Basis von Wartungsplänen abbilden, als auch ad-hoc Wartungen anlegen und rückmelden.

Integrieren Sie die Lösung direkt in SAP

Ihre Prozesse laufen ab sofort vollständig digital ab. Durch eine dauerhafte SAP Integration sind Ihre Daten immer in Echtzeit verfügbar und aktuell. Vertrauen Sie uns als SAP Silver Partner! Ein reibungsloser Projektablauf steht für Sie an erster Stelle? Vertrauen Sie unserer Erfahrung und unserem Know-How für ein erfolgreiches Projekt.

White Paper

Mobile SAP Anwendungen für jede Prozesswelt

Sie möchten Ihre Instandhaltungs-, Produktions- oder Inventurprozesse mobil, transparent und effizient gestalten?

Unsere FlexMobile SAP Apps erweitern den SAP-Standard weit über das EWM-Umfeld hinaus – und bringen Digitalisierung direkt auf das Shopfloor-Level.

Abbildung des mobilen Instandhaltungsprozesses in SAP

mobiler Instandhaltungsprozesses

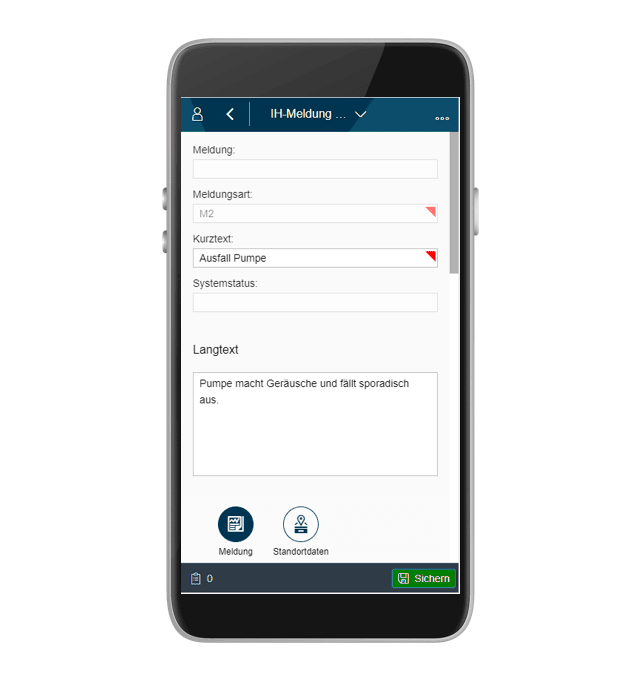

So legen Sie eine Meldung an

Die Meldungsanlage in der mobilen Instandhaltung bietet viele unterschiedliche Möglichkeiten. Sie haben folgende zur Auswahl:

So können Sie im Prozess die Variante nutzen, die am einfachsten umzusetzen ist. Ihr Mitarbeiter vor Ort kann so beispielsweise eine Meldung direkt mobil anlegen und muss dafür nicht an seinen stationären Arbeitsplatz und PC zurückkehren. So entfallen zusätzlich die papierbasierten Prozesse.

Weiterhin haben Sie die Möglichkeit, auch Wartungspläne zu hinterlegen. Diese ermöglichen Ihnen eine vorausschauende Planung und Einteilung Ihrer Mitarbeiter, da Meldungen in regelmäßigen und planbaren Abständen eingehen.

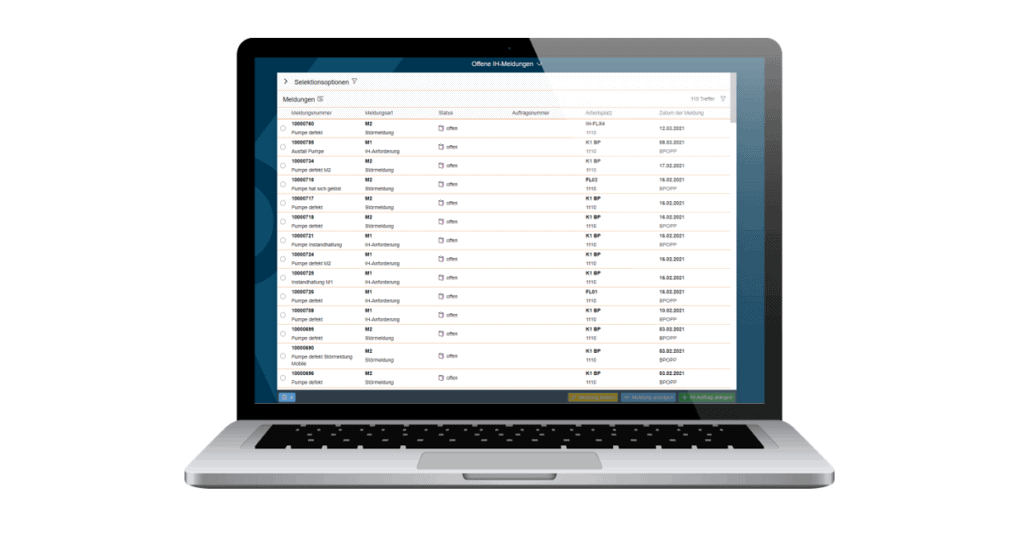

So bearbeiten Sie Meldungen

Im Rahmen der Meldungsverwaltung spielt nicht nur die Anlage dieser Meldungen, sondern auch die Bearbeitung und Anzeige angelegter Meldungen eine große Rolle.

Die mobile Instandhaltung mit SAP bietet Ihnen auch hier den entscheidenden Vorteil, dass Sie Ihre Meldungen in Echtzeit und direkt vor Ort mobil einsehen können. Die Bearbeitung der Meldungen kann direkt am Einsatzort geschehen, was erneut Zeit einspart.

mobiler Instandhaltungsprozesses

So geben Sie Meldungen frei und legen einen Auftrag an

Nachdem Meldungen in Ihrem System eingegangen sind, müssen Ihre Mitarbeiter diese qualifizieren und Aufträge anlegen. Hierbei haben Sie die Möglichkeit, jede Meldung einzeln zu bearbeiten oder Meldungen zu einem Auftrag zu bündeln. Dies bietet sich besonders bei Inspektionsrundgängen an.

Als Instandhaltungsbeauftragter haben Sie hier die Möglichkeit, die angelegten Meldungen zu prüfen und anschließend als Auftrag anzulegen. Zudem können Sie bereits erstellte Aufträge ändern und Prioritäten vergeben. All diese Änderungen können Sie intuitiv per Drag&Drop im Meldungscockpit vornehmen und überwachen.

In diesen Aufträgen können Sie außerdem direkt die Zeitplanung für Ihre Mitarbeiter vornehmen und genaue Vorgänge sowie Komponenten hinterlegen. Zudem besteht für Sie die Möglichkeit, direkt in der App eine BANF Anforderung passend zum Auftrag zu stellen sowie direkt Objekte aus Ihrer Objekteliste hinzuzufügen. Auch hier unterstützt Sie das übersichtliche Meldungscockpit bei der Bearbeitung.

Je nach Rolle des Mitarbeiters können rollenbasierte Ausprägungen im Cockpit angezeigt werden. Beispielsweise werden spezielle Filter wie „Meine Meldungen“ und „Meine Aufträge“ dargestellt.

Durch das mobile Management der Instandhaltung entfallen papierbasierte Prozesse und die redundante Datenerfassung vollständig, da Ihre Mitarbeiter diese just in time direkt in SAP hinterlegen.

mobiler Instandhaltungsprozesses

So teilen Sie Aufträge mit dem Planungscockpit zu

Nachdem Sie aus den Meldungen Aufträge angelegt haben, müssen diese an Ihre Mitarbeiter verteilt werden. Dies können Sie im Planungscockpit vornehmen. Per Drag&Drop können Sie die Aufträge Ihren Mitarbeitern zuweisen. Durch die direkte Integration eines Kalenders mit Schichtmodell und Feiertagen, können Sie die Aufträge noch einfacher einplanen.

Ihre Vorteile des Planungscockpits

Das Planungscockpit visualisiert Ihnen durch unterschiedliche Farben zudem den Status der einzelnen Aufträge und bietet Ihnen so einen guten Einblick über den Arbeitsfortschritt. Ein zusätzliches Alerting-System informiert den Instandhaltungsverantwortlichen aktiv bei Abweichungen oder Störungen im System.

mobiler Instandhaltungsprozesses

So erhalten Sie eine Teil- und Endrückmeldung

Ihre Instandhaltungsmitarbeiter können dank der mobilen App für die Rückmeldung direkt am Einsatzort den Auftrag quittieren. Als Zusatzfunktion kann hier die Arbeitszeit intuitiv durch eine Art Stoppuhrsystem aufgezeichnet werden und direkt in SAP im Auftrag hinterlegt werden.

Weiterhin haben Sie hier die Möglichkeit, Fotos und Videos hochzuladen, um so die Lösung oder einen Arbeitsfortschritt zu dokumentieren. Weiterhin können zusätzliche Informationen wie Zeichnungen oder Handbücher direkt vor Ort aufgerufen werden.

Bei einer vollständigen Wartung bzw. Lösung des Problems kann Ihr Instandhaltungsbeauftragter den Auftrag direkt vor Ort mobil endrückmelden. Sollte die Arbeit in der Zwischenzeit unterbrochen werden, ohne dass das Problem final behoben wurde, findet eine Teilrückmeldung statt. Der Auftrag kann anschließend zu jeder Zeit von einem Ihrer Mitarbeiter weiterbearbeitet werden.

So dokumentieren Sie die Materialentnahme und -rückgabe

Für eine kostenstellenbezogene Abrechnung ist die Zuordnung von verwendeten Arbeitsmitteln notwendig. Hierbei unterstützt Sie ebenso die App zur mobilen Rückmeldung von Arbeitsmitteln.

Ihr Instandhaltungsbeauftragter kann bereits im Vorfeld relevantes Material im Auftrag hinterlegen. Hierbei kommt es durch den bearbeitenden Mitarbeiter zu einer geplanten Warenentnahme.

Zudem kann Ihr Mitarbeiter selbst zusätzlich benötigtes Material anfordern und aus dem Instandhaltungslager entnehmen. Hierbei spricht man von einer Ad-Hoc Entnahme.

Das verwendete Material wird in beiden Fällen direkt in SAP gebucht und dem passenden Auftrag zugeordnet.Nachdem Meldungen in Ihrem System eingegangen sind, müssen Ihre Mitarbeiter diese qualifizieren und Aufträge anlegen. Hierbei haben Sie die Möglichkeit, jede Meldung einzeln zu bearbeiten oder Meldungen zu einem Auftrag zu bündeln. Dies bietet sich besonders bei Inspektionsrundgängen an.

mobiler Instandhaltungsprozesses

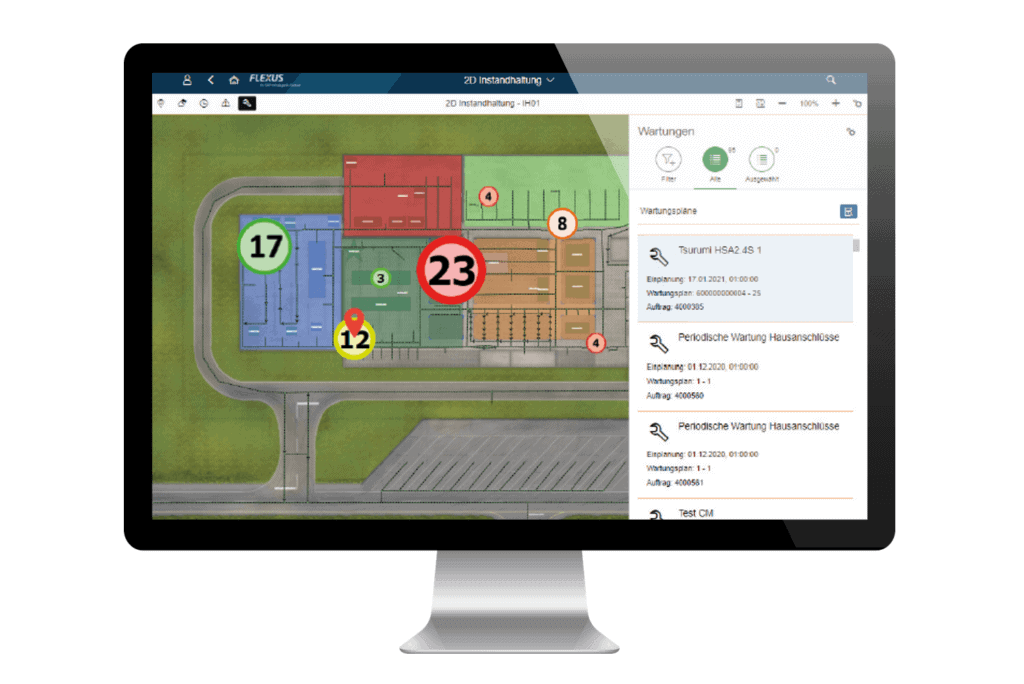

Permanente Verbesserungen mit dem Instandhaltungs-Dashboard

Dashboards übernehmen eine entscheidende Rolle für die Sicherung von Unternehmensprozessen. Mit dem Dashboard für Ihre mobile Instandhaltung erhalten Sie zu jeder Zeit einen Echtzeit-Einblick in die aktuelle Situation und Auftragslage. Das Dashboard visualisiert Ihnen alle aktuellen Störungen sowie die Auslastung und Kapazität Ihrer Mitarbeiter.

Weiterhin erhalten Sie einen Überblick zum Arbeitsfortschritt, indem unterschiedliche Status farblich visualisiert werden. Zudem können Sie sich Ihre offenen Aufträge nach Priorität filtern und anzeigen lassen.

Als besonderes Highlight wird Ihre IST-Situation auf einer 2D-Werkskarte dargestellt. Sie haben so alle Störungen auf Ihrem Gelände im Blick.

mobiler Instandhaltungsprozesses

Anlagen und Dokumente verwalten

Die Anlagenverwaltung als übergeordneter Bereich der mobilen Instandhaltung beschreibt alle Prozesse und Funktionen, die Ihnen den gesamten Instandhaltungsprozess durch den Einsatz mobiler Flexus Apps vereinfachen. Darunter fallen folgende Funktionen:

So ordnen Sie Fotos und Dokumente der Meldung zu

Sie haben die Möglichkeit, den Schadensfall bzw. Defekt sofort per Foto zu dokumentieren oder passende Maschinenbaupläne zu hinterlegen.

Diese Bilder und Dokumente werden direkt in SAP mit dem Auftrag verknüpft, sodass der eingeteilte Mitarbeiter diese Informationen zur Bearbeitung vorliegen hat und jederzeit mobil darauf zugreifen kann.

So generieren Sie automatische Mails

Am Instandhaltungsprozess sind mehrere Personen innerhalb Ihres Unternehmens beteiligt. Informationen zur Bearbeitung des Instandhaltungsauftrags sind für all diese Mitarbeiter von Relevanz. Hierfür eignen sich Statusberichte, die automatisch generiert und per Mail an die hinterlegten Personen verschickt werden.

Der Informationsfluss in Ihrem Unternehmen ist so durchgängig gewährleistet und bei Bedarf können Kollegen oder Vorgesetzte eingreifen und unterstützen. Dieses Verfahren ist zudem von Vorteil, wenn unterschiedliche Mitarbeiter eine Störung beheben, um den Arbeitsfortschritt zu überwachen. Die manuelle und zeitintensive Benachrichtigung untereinander entfällt komplett – das System übernimmt diese Funktion automatisch.

So nutzen Sie die integrierte Unterschriftenfunktion

An verschiedenen Stellen in Ihrem Instandhaltungsprozess ist es notwendig, einzelne Prozessschritte mit einer Unterschrift zu bestätigen. Ohne eine mobile Instandhaltungslösung erzeugt dies einen hohen zeitlichen und bürokratischen Aufwand, da die Unterschriften manuell auf Papier erfasst werden und anschließend händisch von Ihrem Mitarbeiter dem SAP Auftrag zugeordnet werden müssen.

Hierbei unterstützt Sie die digitale Unterschriftenfunktion: Ihnen ist es möglich, an beliebigen Schritten in Ihrem Prozessablauf eine Unterschrift zu verlangen. Ihr Mitarbeiter kann diese digital auf seinem mobilen Gerät anfertigen und abspeichern. Diese wird automatisch als Bilddatei dem Auftrag in SAP zugeordnet. Der Vorteil: eine schnelle und lückenlose Dokumentation!Ihre Prozesse laufen ab sofort vollständig digital ab. Durch eine dauerhafte SAP Integration sind Ihre Daten immer in Echtzeit verfügbar und aktuell. Vertrauen Sie uns als SAP Silver Partner!

Kontakt aufnehmen