Tugger trains are mainly used based on average transportation requirements and are therefore set up to operate on fixed routes and at fixed departure times. Internal processes, however, are subject to major and short-term fluctuations, especially in the field of Production and Warehouse Management.

You can counteract these with the fully dynamic Tugger Train Control for SAP since transport tasks are generated by taking into account the current situation in the plant. These are also checked in real-time and changed if necessary.

I Your departure times and routes are thus controlled completely dynamically. A fluctuating task load can as such be counteracted by scheduling or rescheduling.

Reduced

travel distances

Minimized

empty runs

Saving

resources

Increased

delivery reliability

TUGGER TRAIN CONTROL – NOW EASIER THAN EVER!

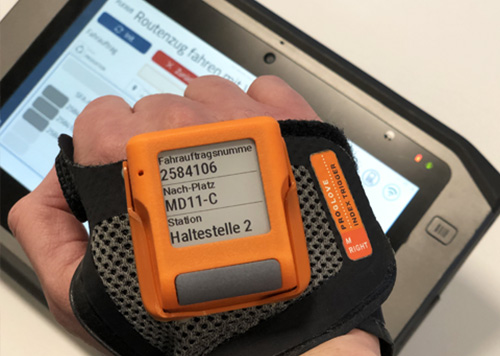

With the integration of the new MARK display from ProGlove, you can optimize your processes related to the Tugger Train Control even further. “Hands-free” scanning processes greatly accelerate and facilitate the unloading and loading process of the tugger train.

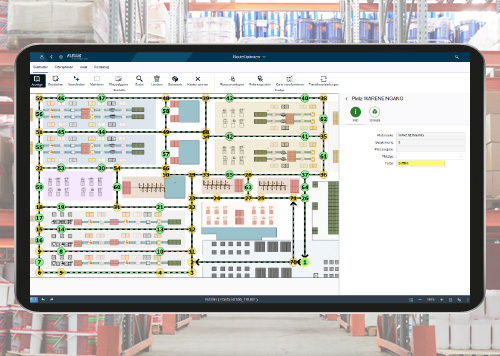

1. Factor in the plant layout and warehouse structure

With the Flexus Route Optimizer, routes and directions are defined based on your CAD plant layout. It also lets you define pick-up and delivery points. But you do not have to define fixed routes. The connection to your SAP system is set for each individual node.

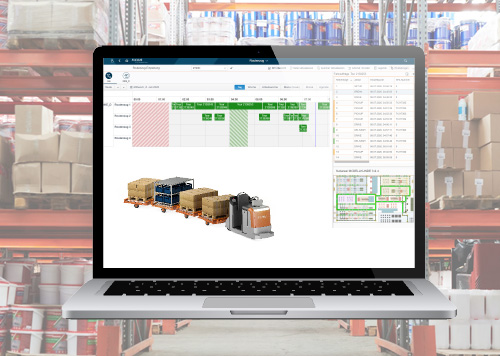

2. Transport task creation & tour optimization with heuristics

The transport task pool for your tugger trains is automatically filled directly from SAP (triggered directly from your SAP MM, WM, EWM, PP system, from external MFS systems or manual creation).

The integrated heuristics optimizes your tugger trains holistically. Your routes are optimized taking into account your resources, your plant data and your transport task data.

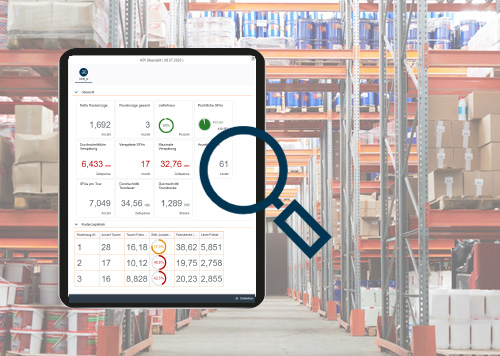

3. Visualiziation of live operation in the dashboard

Your fully dynamic tours and start times can be viewed live in the Cockpit and can be edited manually if necessary. You can get displayed individual tours with regard to the different actions (attaching, loading, runs, unloading, …) if required. An additional tour animation visualizes the respective routes for improved traceability.

4. Live deployment on tugger trains with mobile apps with partially/fully automated tugger trains

The mobile SAP Fiori apps display subsequent actions to your driver. The next actions and destinations are visualized intuitively, and material pick-ups/drop-offs are confirmed directly via the app (Combination with MAR Display from ProGlove).

5. Permanent improvement with integrated KPIs

A number of different key figures enable you to directly identify possible challenges and to set improvements. You can now directly answer questions about delivery reliability, capacity utilization, number of completed tours, reported malfunctions with the Tugger Train Control for SAP.