In many projects, the subject of logistics optimization is kicked off with a focus on warehouse processes. It is important, however, not to lose sight of the processes on the plant premises. SAP EWM is a key module for the perfect implementation of delivery processes, shipping processing, but also for internal stock transfers with location and route optimization. Transportation Management (TM), as another module, handles the logistics planning of the means of transportation in conjunction with and integration of service providers and suppliers. This is precisely where EWM Yard Management steps in –as a means of bridge building from TM to EWM.

In this article, we would like to provide you with detailed information on the subject of Yard Management in SAP EWM. Interesting facts about current techniques and different applications, integration into existing logistics processes, useful functionalities, hardware components, but also about roll out strategies and reports from productive projects and current roll out projects.

SAP EWM Yard Management: The next step in the optimization of intralogistics

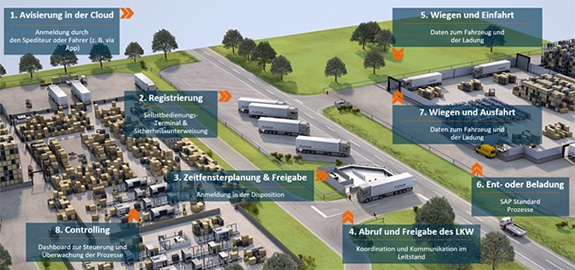

Efficient logistical processes on and in front of the plant premises pose a major challenge for companies. Delayed trucks mess up the actual planning in commissioning, and waiting trucks block entrances and exits or require parking spaces that are not available. Additionally, uncoordinated ramp assignments require the forwarding agent to spend more time than originally scheduled. These and some other issues in the domain of yard and ramp management can basically be solved with the use of Yard Management to make the in-plant logistics more efficient and to guarantee the continuously optimized process from TM across Yard into the EWM functionalities.

Which sap yard logistic solutions are available?

The subject of Yard Management is very complex – a large number of manufacturers offer solutions, functionalities and hardware, running directly in SAP, as an external cloud solution from SAP or externally, which can be rented or licensed, ranging from a couple of €100 per month up to seven figure sums. But what should be considered during planning and how steep are the implementation costs and time lines? After all, nobody wants exploding costs or functionalities that are not realistically operable in practice and consultants with experience from other modules but without any real know-how in the yard sector. Many manufacturers offer solutions with specialized functionalities or equip their hardware with rudimentary process solutions, but ignore the overall process.

The EWMinds expert network, formed by Flexus AG, Priotic GmbH, IT-Forum and OPAL Associates Holding AG, puts emphasis on the full scope of solutions, functionalities and processes in the SAP environment. The focus is on SAP EWM, but the scope of application has been extended to include global SAP processes in order to account for process chains of manual processes, production logistics, maintenance, but also the MM processes and WM warehouses that are still widely used to this day.

Step 1: Key factors for determining the scope of solution

This question is often raised in our projects but also during initial analyses and web sessions. A general recommendation does not exist but based on experience from past projects, shared discussions, and corporate strategy planning, it is possible to approach the issue in an objective-oriented and structured manner.

The following key factors for determining the scope of functionality should be included in the assessment:

- Existing or already planned infrastructure of the location

- Strategic IT infrastructure planning (on-premise, cloud, etc.)

- Use EWM yard management processes only or also WM, IM, PP or EAM

- Mapping of NON-EWM or NON-SAP processes (CEP service providers, craftsmen or recyclable material transports)

- Internal resources capacity and project durations

- Direct online integration of service providers and suppliers for ASN (Advance Shipping Notice)

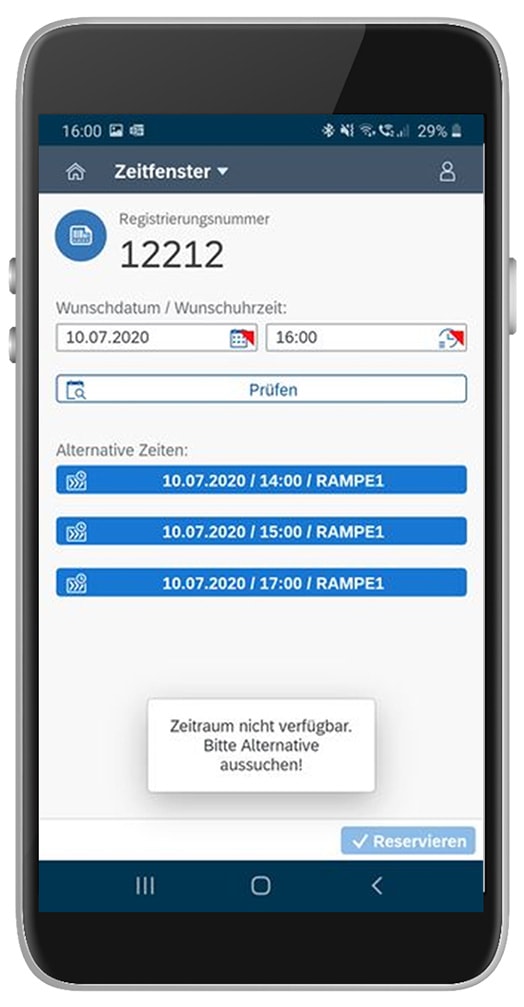

- Online / Offline integration of truck drivers via apps for Android / iOS

- Use of external hardware (self-service terminals, scales, license plate recognition, etc.)

- Product range with handling rates and dimensions

- Quantitative observation of yard processes (number of trucks, transports, etc.)

- Already formulated objectives by the executive board

Step 2: Overview of potentially required and meaningful functionalities

Not all functionalities presented here may be required or meaningful for your site in the specific case. Identifying and understanding the key factors is the basis of any project.

- A self-service portal as an interactive service / supplier platform

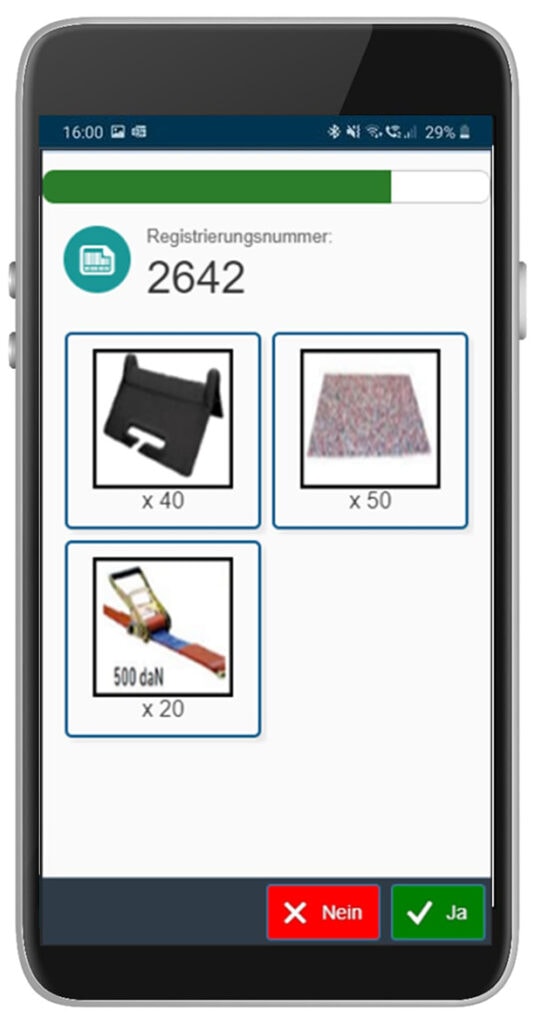

- Active integration of drivers through mobile solutions

- API for integration of external transport portals or Transport Management (TM)

- API for integration of external hardware, third-party integration

- API for integration or use of the modules EWM, WM, IM, PP, MES, PM

- Time slot planning (automatic, manual, appointment scheduling, appointment management, serial appointments)

- Dock management with topology, capacities, block and maintenance planning

- Notification management for communication (email notifications, SMS, pager, information board, mobile apps)

- Activity management with dashboard, alarm function, notifications, emergency notifications

- Updates, notifications, data and monitoring in real-time

- Reports, analyses and statistics

- Template creation for roll outs to other processes or locations

- Wizard / Customizing Portal to implement or extend processes by the own IT or business department

- GPS, location tracking, display of positions, route management / optimization of the internal plant traffic

- Trailer / container management, swap body handling

- Document management for dockets, SAP document printing, signatures, scan of external receipts

- Authorization / Access control management with roles, profiles, centralized and decentralized maintenance

- Special processes, e.g. dangerous / hazardous goods handling, gases, liquids, bulk goods

- Check for dangerous goods, or hazardous goods, with digital checklist and the ability to save the data in the system in real-time

- Scheduling of additional resources (crane, excavator, special vehicles / personnel) for loading / unloading

- Invoice management (billing & invoicing, proof of costs, special expenses)

- Safety management (load safety, explanation videos, questionnaires, technical safety equipment, control functions)

- Support for different languages via a multilingual touch display

- Weight monitoring for loading / unloading

- Transporeon

- SAP Ariba

Step 3: Possible technological variations and SAP integrations

After analysis and identification of the required key factors including the required range of functionality, the next step is the selection of the yard system. The SAP solutions established on the market are classified below:

Yard functionality in SAP WM

This SAP solution delivered in the Warehouse Management (WM) system can only be considered as an initial functional approach. The developments here took place around the year 2002 and a real functional and technical further development has not taken place since then. Meanwhile, WM has been discontinued by SAP and is being replaced by EWM.

SAP Yard Logistics 2.0 (YL)

SAP Yard Logistics (YL) is a standalone solution, is installed as a separate module and is only recommended to be used on the SAP S/4HANA system. It can be operated on the SAP SCE Platform (SAP Supply Chain Execution) as well as in standalone mode. According to SAP, the Yard module is positioned as a link from TM to EWM. SAP Yard Logistics is based on SAP EWM 9.3. and is built as a technical foundation around master data, data structures and the processes of EWM. In other words, sap yard logistics is not possible without EWM.

The use of WM and other classic modules is only possible with workarounds that require complicated Customizing and supplementary developments. The range of functionality is very extensive: it is possible to map very complex processes, to add a wide range of additional functionalities from 3D to GPS / RFID and to integrate SAP DAS (Dock Appointment Scheduling) and SAP TM (Transportation Management). This comes at a price in the form of complex Customizing and the SAP-typical transactions overflowing with information and functions. For power users who want to keep an eye on even the smallest detail, this is an excellent solution. For truck drivers and gate personnel, however, there is room for improvement in terms of ease of use, or user convenience, and transparency. The finished transactions used here make only rudimentary use of the possibilities of Responsive Design and a good UI. The Yard Cockpit with 2D view is a good approach for gaining insight into the current situation and position of the transport unit. The 3D view, in contrast, is nothing more than an attempt to use modern technology in a promotionally effective way.

Functionalities of Yard Management in SAP EWM (SAP Extended Warehouse Management)

With this solution, SAP has further extended the range of functionality. It is now possible to speak of the first real yard solution from SAP. The application is completely integrated in EWM and primarily supports these EWM processes. Standardized connection of hardware (e.g. self-check-in terminals) and extended functionality for time slot planning, operable dialogs for employees and drivers are missing or are based on outdated technologies. Extensions and connections to e.g. self-check-in terminals, scales or license plate recognition must be implemented by additional programming.

The yard management in SAP EWM supports comparatively simple yard processes and handles relevant resources in the form of transport units (TUs).

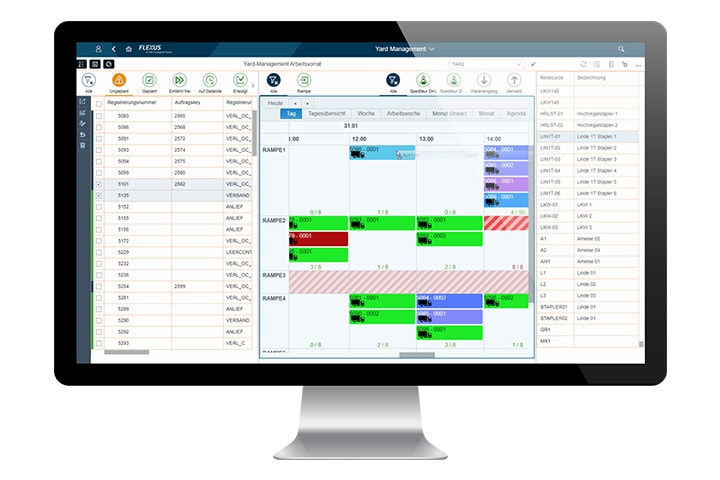

The solution: Flexus Yard Management for SAP

Flexus Yard Management was developed to address the lack of functionality in WM Yard and EWM Yard and in response to the very complex SAP Yard Logistics.

Goals:

- Creation of a standalone solution implemented and programmed with SAP

- Use of the systems SAP ECC with Netweaver and S/4Hana

- Independence and concurrent use and integration of the SAP modules IM, WM and EWM

- Integration of hardware from different manufacturers (plugin-compatible)

- Dialog creation as a basic framework for use with SAPGUI and SAP Fiori

- Operational functionality in all frontends of Windows, Android and iOS

- Simple, intuitive and streamlined dialogs for truck drivers and logistics employees

- Customizing and parameterization is simple, yet suitable for a wide range of process variations

- Drastic reduction of roll out times due to templates that come ready out of the box

- Customization of templates for different processes and locations

- Activation of innovative technologies from APC (ABAP Push Channel) to GPS tracking on demand

- Develop specific add-ons in cooperation with the customer

- Maintenance by support

Furthermore, since this is a standalone solution in the SAP environment, the customer is not restricted to processes and functionalities in SAP WM or SAP EWM. Processes from MM, PP and EAM can be integrated, but also processes for recycling centers, CEP service providers and craft businesses can be mapped, which cannot be realized with classic SAP modules. For this purpose, the solution can be used as a standard two-system landscape or a cloud-based solution. The latter can additionally be supported by an additional cloud via IDP in order to integrate an additional user management. As an enhancement and optimization, the Flexus Yard solution can also significantly improve the SAP YARD Logitics 2.0 solution.

It is also possible to roll out the systems using templates, which means that the new software programs can be implemented and used at individual locations on a practically ad hoc basis. In combination with the Flexus Translation Tool, the entire process can be transformed quickly into other languages. This makes international roll-outs feasible. As a result of the simple relationship of the required apps, preferably via Google Play or the Apple Store, not only plant-internal employees but also external forwarding agents can be provided with the necessary applications to achieve an efficient turnaround time of the trucks.

SAP Yard logistics – summary

For NON SAP solutions, we see no benefit when looking at the highly integrative strategy for yard management in SAP EWM systems, even if one were to consider the costs and presumably shorter implementation timelines. Interfaces and potential extensions are the cost drivers here for the business until this solution approach fails.

An EWM yard management solution with SAP is the right approach for all SAP customers in general. After all, the solutions can directly access and update all SAP objects and master data without any interface. On top of this, they all make use of the SAP basic technologies, which means that a seamless transfer of knowledge is ensured. With the use of the ABAP programming language as source code, the SAP solutions are openly accessible and can be changed using repair keys or extended using a redefinition of classes and methods. Additionally, the solutions rely on the known transport channels and therefore facilitate the coordinated transport of development and customizing settings.

There is no general answer to the question about which yard solution is the right one. Nevertheless, we can in principle recommend not to use the standardized Yard WM and Yard EWM solution as things stand today. Both solutions lack potential for the future.

SAP Yard Logistics takes a more complex approach compared to the Flexus Yard solution. This approach can be expected to be very expensive in terms of consulting costs and time lines leading up to the productive implementation. The perfectly conceptualized process flow from TM across Yard to EWM is an interesting option. Unfortunately, it is not always a viable option in practice because WM warehouse, IM processes and many manual NON-SAP processes reveal the inflexible nature of this tool in particular.

The Flexus Yard Management shows its strengths here: Plugin-compatible with instantly operational sample processes greatly reduce the project volume in agile projects. In line with the motto: it is easier to criticize and change than to fully redesign on the drawing board. This means that the specialist teams can refine their ideas on the operational system and customize and test the process perfectly and quickly.

Another variant: A combination of the classic SAP Yard Logistics with the plugins of the Flexus Yard solution – in this way it is possible to introduce the classic SAP standard and at the same time not miss out on the innovative and practice-oriented add-ons of the Flexus Yard Management.

Expert network EWMinds

Together with our partners Priotic GmbH, IT-Forum and OPAL Associates Holding AG, we offer in the expert network EWMinds the complete handling of logistics processes with SAP EWM. As a Business Suite provider, we consult our customers holistically during the migration or new implementation of SAP EWM with own SAP add-ons, tools and hardware.

Author – Stefan Popp

Executive Director

As CEO of Flexus AG, he knows the company inside out and how to successfully help customers achieve efficient intralogistics with optimized SAP solutions.