Arrival at the loading ramp in many cases uncoordinated

After the truck has been weighed at the gate and made it through, the driver must locate the correct loading ramp. This often takes place in an unstructured approach because the driver usually does not know exactly where to go and has only been told the information by the gatekeeper. This not only causes a pointless waste of time but also poses a risk to safety due to the increased traffic volume on the plant premises.

Digitalization of process flows

If the yard logistics is controlled using the SAP-based Flexus Yard Management, the loading ramps are released on time with a precise display of the position that needs to be moved to via cockpits, SAP transactions or apps. The driver receives the messages on pager, mobile phone or by display on info boards on the plant premises. As a result, trucks will arrive more quickly at the appropriate ramp for unloading and loading.

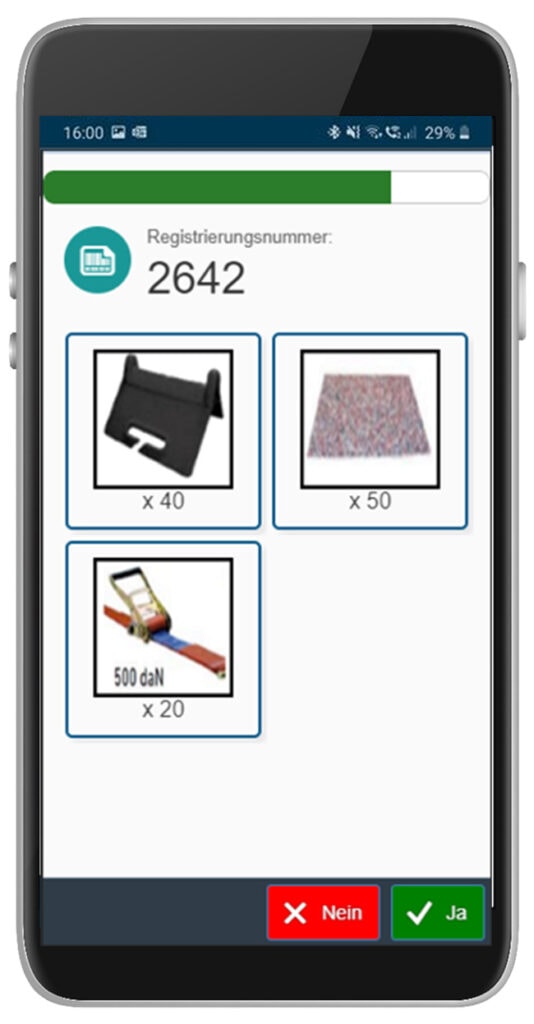

The forwarding agent usually carries dockets along which are handed over to the loading foreman at the ramp and signed. The unloading and loading are both documented manually and on paper. If the loading is done by the resident company, there cannot be any documentation about the load safety by the forwarding agent in this case. The situation is different when Yard Management is used because the signature is primarily made via SAP GUI transactions in the Flexus Mobile Browser on a mobile device. This also allows to take photos of the loading and load safety and to document this directly in SAP. It is also possible to print the loading documents with signatures.

The forwarding agent heads back to the gate after loading or unloading. Once there, the truck will be weighed again, and in many cases the gatekeeper will once more manually enter the data into the paper-based gate book. With Yard Management, in contrast, the driver repeatedly identifies himself with his barcode on the mobile device at the terminal and also performs the exit weighing here. After this, the exit can be released.

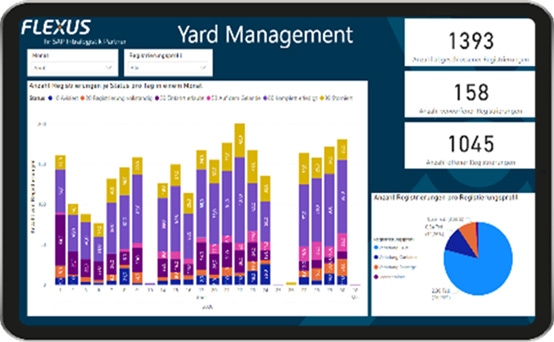

Yard dashboard for real-time evaluations

Additional evaluation tools and real-time analyses enable the entire process to be mapped transparently and quick intervention in case of malfunctions. The process is thereby optimized for the long term. Potential key figures include evaluations of resource types, priorities, due dates, or travel times.

But Flexus Yard Management goes even further. The actual coordination on the plant premises is not the only thing that is mapped optimally via the mobile solutions and apps. The check-in and advance coordination of incoming deliveries are also controlled centrally.

Author – Julian Lother

Team Lead Yard Management

Working at Flexus, he successfully implements projects in the field of Yard Management. As a consultant in this field, he optimizes the entire process of Yard and Ramp Logistics with SAP solutions by Flexus!