AGVs are currently being used, tested or at least their usefulness is being examined in almost all production facilities and warehouses. The goals for this are manifold: saving costs, avoiding errors, reducing dependencies, increasing availability or a mixture of all. However, there is always one thing at the heart of it: automation. This enables selected processes in intralogistics to be carried out without the human factor.

Why you should standardize processes for AGVs

Automated driverless transport vehicles can bring several benefits to your business, but they also bring new challenges. Trained employees can react to unforeseen events, find new solutions and creatively avoid disruptions. Problems with occupied storage spaces, oncoming traffic or damaged goods are currently solved by your employees on a daily basis. And if they can’t fix them themselves, they have other qualified colleagues in your company as contacts to whom they can report these problems.

However, AGVs can very rarely find all these “creative” solutions to unforeseen events and solve problems that have arisen on their own. You need structured, planned frameworks and processes.

Where flexrules. can be used effectively in your AGV project

The foundations for functioning, automated processes with driverless transport vehicles are plannability and structure. Translated to your intralogistics, this is correct and completely collected data. These are required by all driverless transport vehicles in order to carry out their work independently. Unfortunately, correct data is not 100% available in any company. In every plant there have already been faulty master data, in every production there are missing postings and transaction data. All these small data errors are usually not a big problem and will be corrected by your staff when they are noticed. However, as soon as this erroneous data becomes the basis for automated processes, it becomes problematic:

- How should an AGV pick up a container whose material has been booked incorrectly?

- May a driverless transport vehicle pick up a pallet whose weight was mistakenly set at 500kg instead of 50kg?

- What happens to the current driving jobs if an AGV fails? By whom are these further processed?

- Who ensures that a driverless transport vehicle does not wait for hours at the transfer point for its goods, which have already been lost or booked incorrectly?

In all our projects with AGVs, it has been shown that in any warehouse and production, there can be many small, unforeseen problems due to data errors. Especially due to the multitude of different systems working together, in combination with human processes, these data errors are unavoidable.

For this reason, it is important that you can also react to those problems in an automated way. This is the only way to ensure smooth operation with automated vehicles in your company.

Use ready-made template rules or design your own flexrules. by drag&drop in minutes!

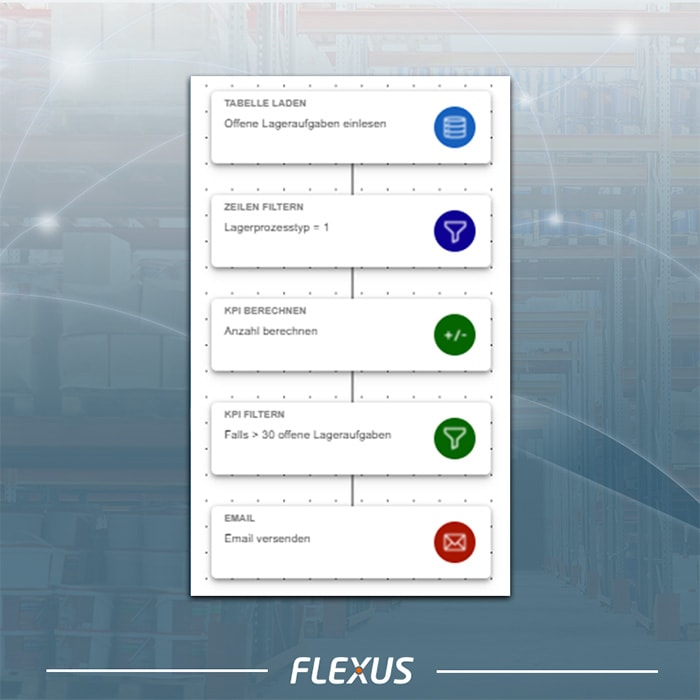

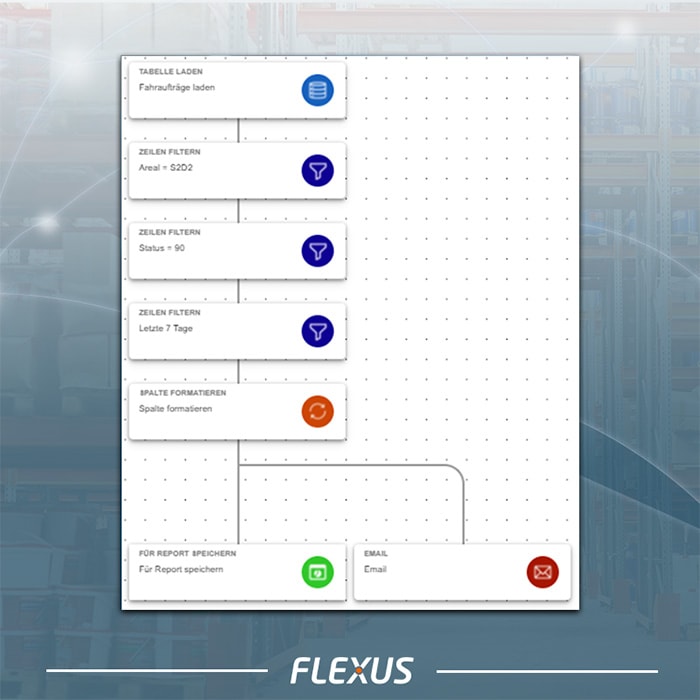

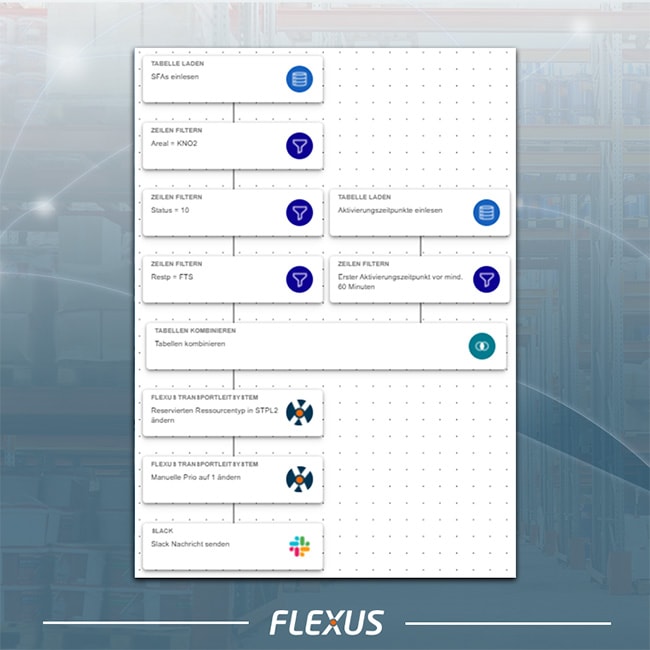

With the flexrules. module, the process flows or business rules in your company can be created based on all data occurring in your SAP system.

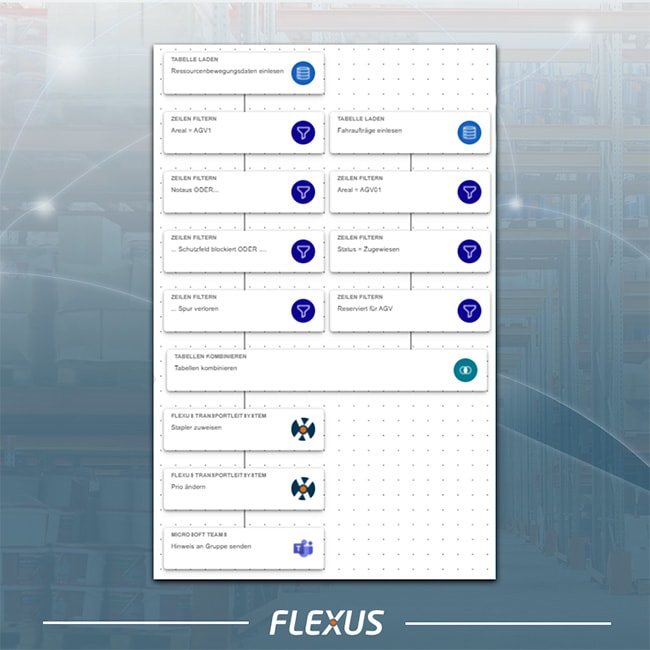

A business rule consists of various elements, which you can combine with each other as you wish and arrange using drag & drop. This modular principle allows you to create countless individual combinations and to monitor and correct all data automatically.

For your new projects, we bring a set of ready-made flexrules. which only need to be adapted by you in a Fiori interface (or also in the SAP GUI).

Shortly before the go-live of your project, you can finally use them to test the data quality ad hoc in the production system and thus ensure the processes. In later operation, these flexrules. are scheduled automatically and executed regularly in the background.

Concrete flexrules. – some possibilities for the process optimization of your AGVs.

| Description | Destination | Action |

| Email me if an AGV is in trouble. | Fast response to errors. | Send email. |

| Send a Microsoft Teams message if AGV utilization rises above 90%. | Scheduling additional AGVs or replacement drivers. | Send Microsoft Teams message. |

| Assign AGV driving jobs to a forklift if they have not been processed after two hours. | “Clean up” of unprocessed AGV driving jobs. For example, if this AGV is loading or in fault. | Assign driving jobs to other resource types. |

| Cancel all AGV driving orders at the end of that day. | Clean data for the next day. | Cancellation / acknowledgement of transport orders |

| Prioritize driving jobs whose assigned AGV is currently loading. | Ensure that these driving jobs are processed quickly. | Prioritize driving jobs. |

| Send me a message with all resources whose “maximum charge” or “maximum speed” has been changed. | Verify changes in master data. | Send messages via email, Teams, Slack or SMS. |

| Send a message if the AGV type “DEMO_01” cannot go to the place “Place_100”. | Send a message if the AGV type “DEMO_01” cannot go to the place “Place_100”. | Send messages via email, Teams, Slack or SMS. |

| Show me all driving jobs that are not assigned to an AGV, but were already created an hour ago. | Review transaction data. | Visualize data as a table or chart. |

flexrules. – Use the advantages to scripts & programming

Most AGV control tools already have the ability to send alerts or respond dynamically to specific situations. However, the advantage of flexrules. is that they were developed completely independently of any data. The flexrules. solution can be used, among other things, in your intralogistics for driverless transport vehicles as well as in your financial accounting. This gives you the advantage that processes can be individually adapted to all situations without development effort.

We provide you with a large set of prefabricated flexrules. which only need to be configured to your requirements. For example, you can change limit values, AGV type designations, or e-mail addresses. However, the real goal is for your company itself to be able to create new, individual flexrules. in the Fiori interface

By also allowing your logisticians to monitor and correct the data and processes themselves, it has been shown that the resulting solutions are often more creative and closer to the real world. Any new data problem or additional analysis that arises in your company can be created as a business rule by your employees in just a few minutes and then executed automatically.

The flexrules. module is a subcomponent of the Flexus AGV control system and is integrated as a modular component into that control system. The Flexus AGV control system for SAP ERP and SAP S/4HANA can be easily integrated into your existing system and enables the control of vendor-independent AGVs via the VDA 5050 standard.

Alexander Popp

SAP Berater TLS

Within the scope of his work at Flexus, he is active in the development of new applications as well as in the consulting and implementation of projects. The focus is on the transport control system for AGVs and tugger trains. Across topics, he is responsible for the development of new flexrules.